Membrane keypad are essentially the specific application of membrane switches in the field of keyboards. We use high-quality basic materials. In the selection of conductive materials, we use advanced conductive inks, metal foils, etc. We have a variety of options for key materials, such as soft and comfortable silicone, elastic rubber and cost-effective plastic.

What is a membrane keypad?

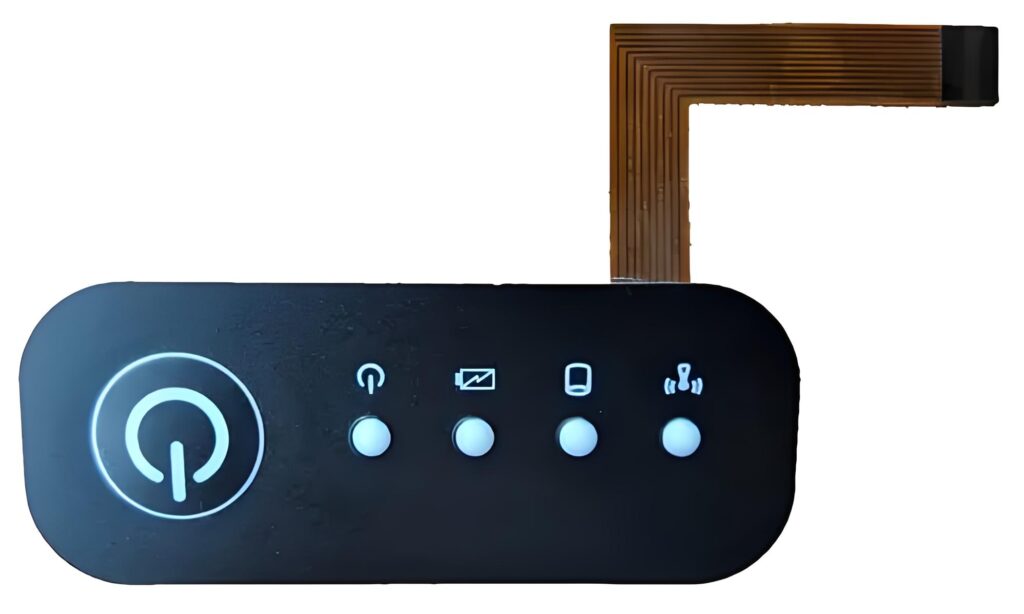

The membrane keypad is essentially a membrane switch. It is an operating system that integrates key functions, indicating elements and instrument panels. It consists of four parts: panel, upper circuit, isolation layer and lower circuit.

When the membrane switch is pressed, the contact of the upper circuit deforms downward and contacts the plate of the lower circuit. After the finger is released, the contact of the upper circuit rebounds, the circuit is disconnected, and the loop triggers a signal. This switch has a rigorous structure, beautiful appearance, good sealing, moisture resistance and long service life.

Membrane switches are widely used in electronic communications, electronic measurement instruments, industrial control, medical equipment, automotive industry, smart toys, household appliances and other fields.

It is a new type of electronic component with good waterproof, dustproof, oil-proof and harmful gas erosion resistance, and stable and reliable performance, light weight, small size and long service life. The panel can be washed without damaging the characters, and the colors are rich and beautiful, making the product more contemporary.

What is membrane keypad design?

Membrane switch design refers to the design of an operating system that integrates key functions, indicator elements, and instrument panels.

Conductive circuit planning: The membrane switch realizes signal conduction through the contact of the upper and lower circuit layers. When designing, the layout of the conductive circuit should be accurately planned to ensure that the upper and lower circuits corresponding to each key can be accurately connected. The width and spacing of the circuit must meet electrical safety standards to avoid short circuits.

Signal trigger mechanism: It is necessary to consider how deep the key is pressed to trigger the circuit to conduct. This involves the selection and thickness design of elastic materials (such as the shrapnel or rubber pad under the key). Different application scenarios have different requirements for triggering force.

Diversified key functions: Membrane switches can integrate multiple function keys. In addition to common numeric and letter keys, function keys can also be designed. For some special-purpose membrane switches, sensors are also integrated to detect the force of the user’s press to provide more accurate operation feedback.

Work with other devices: The design of membrane switches should consider how to work with connected devices (such as circuit boards, displays, etc.). It is necessary to ensure that the signal format sent by the switch can be accurately received and processed by the control system of the instrument to achieve functions such as parameter setting and mode switching.

Surface treatment: In order to improve the texture of the panel, it can be surface treated. For example, frosting can make the panel have a soft gloss and reduce fingerprint residue; high-gloss treatment will make the panel look brighter and more upscale, but it may easily leave fingerprints.

Shape customization: The shape of the membrane switch can be customized according to the shape and installation space of the device. It can be a regular rectangle, square, or round, oval or other irregular shapes.

How to customize membrane keypad?

To customize a membrane switch, many factors need to be considered comprehensively. The first is to clarify the needs, including determining the button and signal requirements in terms of function, considering the physical and chemical conditions in the use environment, and planning the shape, size, color and pattern in appearance.

The next stage is the design stage, which covers circuit design, to ensure that the circuit is reasonable and the interface matches; mechanical structure design, the buttons and elastic structure need to be designed according to ergonomics; appearance design, focus on the panel and overall appearance design.

Then comes the material selection, such as the panel, circuit layer, isolation layer material in the film material, and the rubber pad or metal shrapnel material in the elastic material.

Finally, the manufacturing and testing stage, the manufacturing process must be selected correctly, including printing and lamination processes, and comprehensive quality tests such as function, appearance and environment must be carried out.

Are membrane keyboards waterproof?

The membrane keyboard has a certain waterproof performance. The design of the membrane keyboard usually contains waterproof holes, which allow water to flow out of the keyboard and prevent water from entering the keyboard.

In addition, the keys of the membrane keyboard usually use silicone or rubber materials, which have a certain waterproof and anti-fouling ability. Even if water is accidentally spilled, it will not be damaged immediately.

What are the advantages of custom membrane keyboards?

The advantages of customized membrane switches mainly include the following aspects:

1. Personalized design:

Appearance customization: The color, pattern, font, shape and other appearance elements of the keyboard can be customized according to personal preferences, brand image or the needs of specific usage scenarios. Whether it is pursuing a unique visual effect or needing to match a specific device or environment, it can meet personalized needs.

Function customization: Special function keys can be customized according to the specific needs of users.

2. Meet specific needs:

Special layout: Customize a special keyboard layout according to different usage scenarios and user habits

Special size: The appropriate keyboard size can be customized according to the limitations of the use space or the requirements of a specific device.

3. Good adaptability:

Working environment adaptability: The membrane keyboard has good dustproof and waterproof properties. The customized membrane keyboard can further enhance these characteristics, making it more suitable for use in harsh working environments, such as factory workshops, warehouses, medical places, etc.

Device compatibility: Customized membrane keyboards can be designed according to different device interfaces and communication protocols to ensure compatibility with various devices. Whether it is connected to a computer, notebook, tablet, smartphone, or other special electronic devices, stable connection and normal use can be achieved.

What is the function of a membrane keyboard?

The membrane switch is an electronic component that integrates multiple functions and plays an important role in many devices.

Realize device operation function: The membrane switch is an important way of interaction between people and electronic devices. In electronic devices, instruments and household appliances, it acts as a button or control panel, allowing users to control the device’s opening, closing, mode conversion, parameter adjustment and other functions by pressing the corresponding button.

Status indication: The membrane switch can be integrated with an indicator light to display the current status of the device. On some complex industrial equipment, indicator lights of different colors are connected to the internal circuit of the equipment through a membrane switch, which can intuitively show whether the equipment is in normal operation, standby, fault, etc.

Information display coordination: It can also be used in conjunction with other display components (such as LCD screens) to display relevant information on the equipment. In medical equipment (such as blood glucose meters and blood pressure monitors), the display screen of the equipment will display measurement results, setting parameters and other information under the operation of the membrane switch.

Why choose us to customize the membrane keyboard?

We pay attention to product quality and strictly control from material selection to production process.

1. Material selection

Film material: We use high-quality polyester film (PET), polycarbonate film (PC), etc. as basic materials. These materials have excellent flexibility, chemical resistance and insulation, ensuring the stable performance of membrane keyboards in long-term use.

Conductive material: In the selection of conductive materials, we use advanced conductive inks, metal foils, etc. Conductive inks are easy to print and low in cost, which can ensure the stable conduction of the circuit; metal foils have better conductivity and durability, meeting the requirements of different customers for keyboard conductivity and service life.

Key material: The key material is the key to determining the feel of the key. We have a variety of options, such as soft and comfortable silicone, rubber with good elasticity, and cost-effective plastic.

2. Exquisite craftsmanship

Printing technology: We have advanced printing equipment and technology, such as screen printing, inkjet printing, etc. These printing processes can accurately print conductive lines, patterns and text on the film, with clear lines, bright colors and strong adhesion.

Assembly process: During the assembly process, our workers are proficient in every link and assemble the keys, membrane switches and other components accurately. Strict quality inspection process ensures that each membrane keyboard meets high quality standards and is delivered to customers without defects.

3. Strict quality control and after-sales guarantee

Quality control: We have established a complete quality control system, from the inspection of raw materials, inspections during the production process to the sampling inspection of finished products, every link is not missed. During the production process, we use professional testing equipment to conduct comprehensive inspections on the function, appearance, durability, etc. of the membrane keyboard.

After-sales guarantee: We provide customers with high-quality after-sales guarantee services. If you encounter any problems during use, our professional after-sales team will solve them for you in time.

How to custom silicone keypad?

Demand communication and design confirmation: clarify the function, including operation mode, trigger force, etc., and determine the appearance shape, size, color and other details.

Choose the conductive method: You can choose direct contact conductivity (with carbon particles or conductive ink) or through pot pieces/touch switches.

Mold making: First design the mold drawing, consider the characteristics of silicone, and then make a high-precision mold.

Raw material preparation: Select silicone materials according to performance and environment, mix the raw materials, and control the proportion and process.

Sample production and testing: Produce samples and control process parameters. Perform tests on appearance, size, function, reliability, etc., and adjust and improve if unqualified.

Mass production: After the sample is qualified, mass production will be carried out, and the quality will be strictly controlled. After completion, it will be packaged and shipped.

In short, custom membrane keyboards need to comprehensively consider functional requirements, appearance design, material selection, manufacturing process and after-sales service. As the core component of the membrane keyboard, the performance and quality of the membrane switch directly affect the overall performance and user experience of the keyboard.