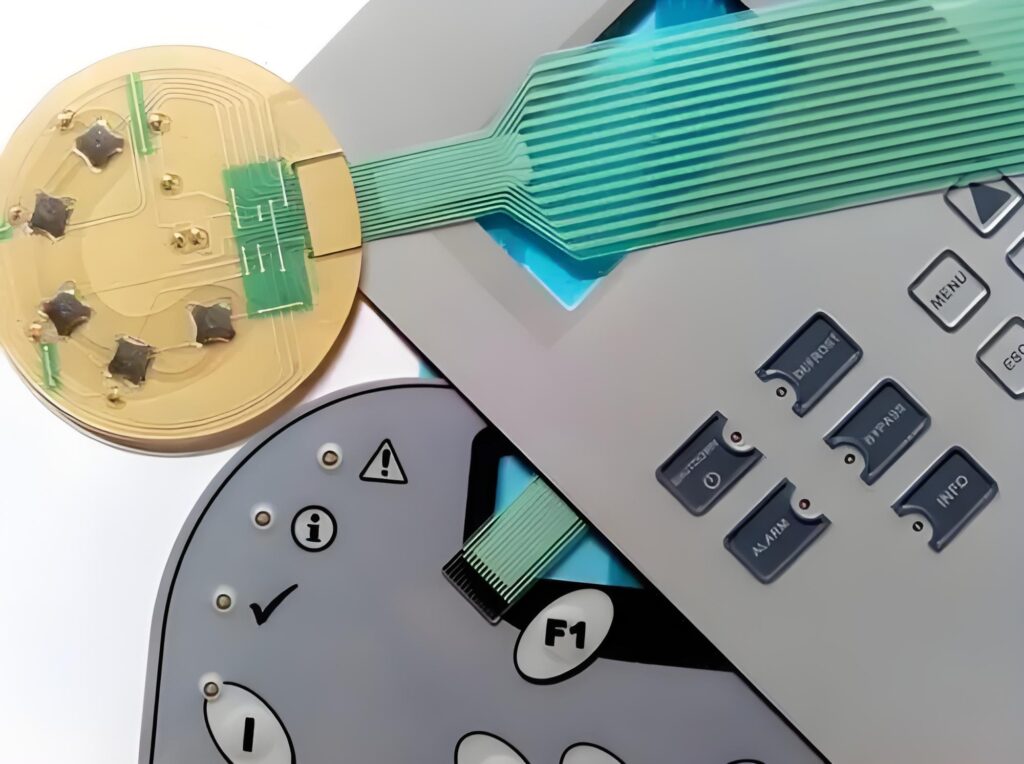

Membrane switch panels have been widely used in many electronic devices with their unique advantages. Membrane switch panels are a new type of electronic component that integrates buttons, indicator elements and circuits. It is usually composed of a panel layer, an isolation layer, a circuit layer and a backing layer.

What is a membrane panel switch?

Membrane panel switch is an operating system that integrates button functions, indicator elements and instrument panels. It is usually composed of four parts: panel, upper circuit, isolation layer and lower circuit.

When the membrane switch is pressed, the contact of the upper circuit will deform downward and contact the plate of the lower circuit to conduct. After the finger is released, the contact rebounds and the circuit is disconnected, thereby triggering a signal.

The structure of the membrane panel switch includes a panel, an upper circuit, an isolation layer and a lower circuit. When external force acts on the panel, the contact of the upper circuit deforms and contacts the lower circuit to form a loop and trigger a signal. When the external force is released, the contact rebounds and the circuit is disconnected.

What does a membrane switch do?

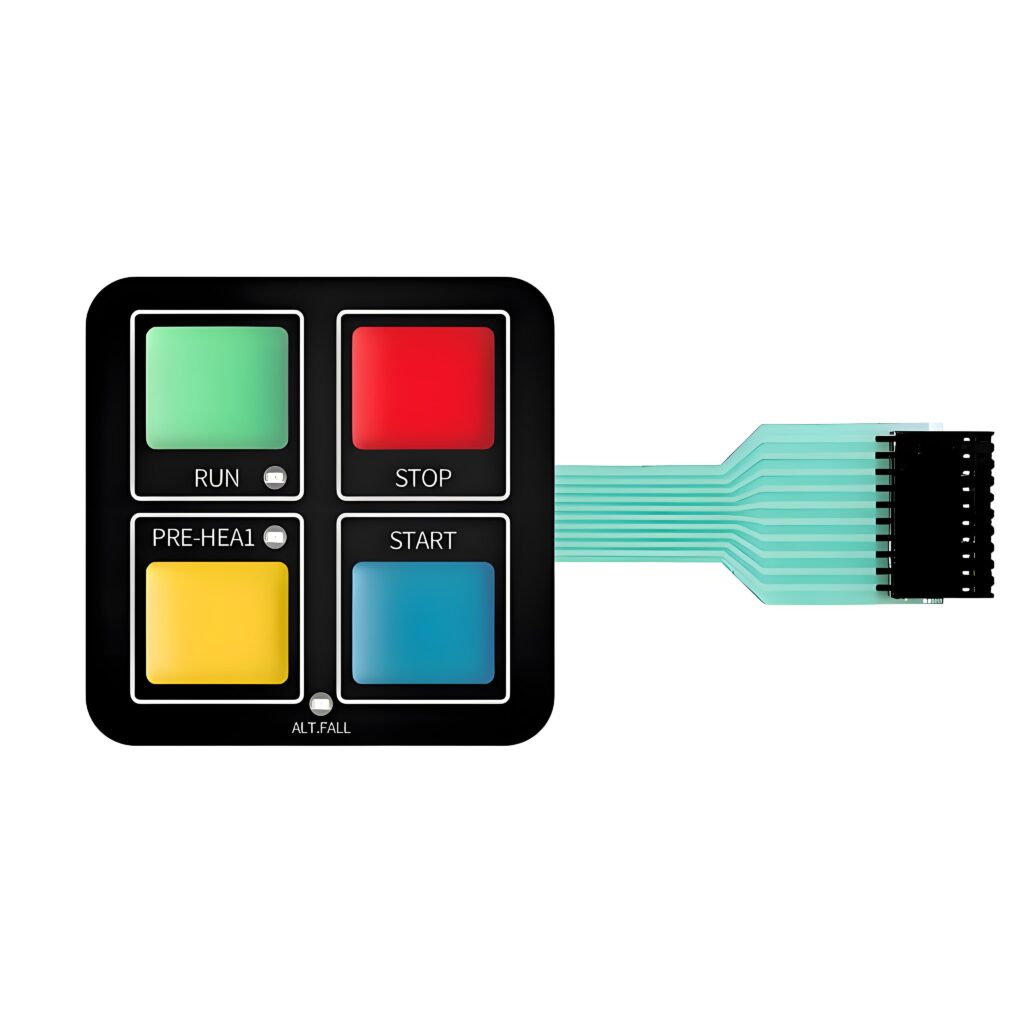

Human-computer interaction interface: used for the operation of electronic products, instruments and meters, and household appliances, to transmit instructions and realize functional control.

Indication and display function: integrated indicator light or combined with display screen to display device status and information.

Equipment protection and sealing: waterproof and dustproof, corrosion-resistant and wear-resistant, protect device circuits and components.

Decoration and aesthetic function: customizable colors, patterns, and texts to enhance the aesthetics of the device and display brand logos.

How good are membrane switches?

Membrane switches have many advantages, including good sealing, strong durability, light weight, small size, waterproof, dustproof, and oilproof, stable and reliable performance, etc.

Good sealing: The overall structure of the membrane switch is sealed and not easy to oxidize. It has good waterproof, dustproof, oilproof, and harmful gas erosion characteristics, and is suitable for use in various harsh environments.

Strong durability: The service life of the membrane switch can generally reach more than one million times. Due to its simple structure and sealing treatment, it is not easy to damage and has stable and reliable performance.

Light weight and small size: The membrane switch can be arranged and combined into a membrane keyboard in design, which is small in size, light in weight, and highly reliable.

Waterproof, dustproof, and oilproof: The membrane switch has good waterproof, dustproof, and oilproof characteristics, and is suitable for various harsh environments.

Stable and reliable performance: The resistance of the membrane switch can be printed materials such as carbon paste, silver paste, copper, platinum, etc., with high performance and stability.

Rich colors: The membrane switch has a beautiful appearance and rich colors. It can be designed according to the design, and the decorative effect is outstanding.

Easy installation: The installation of the membrane switch is adhesive. You only need to peel off the adhesive paper and firmly stick it on the surface of the whole machine, which saves labor and materials and reduces the supporting cost of the whole machine.

What are the disadvantages of membrane switches?

The main disadvantages of membrane switches include the following:

Insufficient hardness: Compared with metal, the hardness of membrane switches is lower and they are easily scratched. Although it has good strength and toughness and can withstand heavy pressure and general falls, long-term use or improper use may cause damage to the appearance.

Not resistant to strong acids, strong alkalis and ultraviolet rays: Membrane switches are not resistant to strong acids, strong alkalis and ultraviolet rays. Long-term exposure to these environments may cause aging or damage to the material.

Conductive properties are affected by the environment: In high temperature environments, the conductive properties of membrane switches may be affected, and the key force and travel may be weakened.

High cost: Although the cost of membrane switches is relatively low, specific technologies and materials are required in the production process, which increases the production cost.

Limited service life: Although the service life of membrane switches is long, generally more than three years, its service life may be shortened under certain extreme conditions of use.

Low finished product qualification rate: Some types of membrane switches (such as capacitive sensing types) have a low finished product qualification rate and are more sensitive to surrounding electromagnetic interference, requiring higher design.

Thickness: Some types of membrane switches (such as LED light guide plates) have a thicker thickness due to the embedded light guide plate, which may affect the overall design of the product.

How long do membrane switches last?

The service life of membrane switches is generally more than 1 million times. The service life of membrane switches mainly depends on their manufacturing materials and design. The service life of membrane switches is usually achieved by the vertical springing of the elastic film. Although it has undergone millions of creeping movements, the creeping amplitude is very small, only 0.1-0.3mm, and the rationality of material selection, the membrane material can withstand more than one million uses without deformation.

Where are membrane switches used?

Electronic communication: Membrane switches are widely used in electronic communication and electronic measuring instruments. Due to their good durability and strong sealing, they are suitable for various harsh environments.

Industrial control: Membrane switches are also widely used in the field of industrial control. They can withstand high-frequency operations without deformation and are suitable for use in industrial environments.

Medical equipment: Membrane switches are used in various control panels in medical equipment. They have good waterproof, dustproof and oil-proof properties and are suitable for medical environments.

Automotive industry: Membrane switches are used in various control panels in the automotive industry. They are light in weight, small in size and easy to install. They are suitable for various control devices inside the car.

Smart furniture: Membrane switches are used in various control panels in smart toys and household appliances. They have beautiful appearance and easy operation. They are suitable for home and children’s toys.

3C electronic products: Membrane switches are also widely used in 3C electronic products, such as mobile phones, tablets, etc., with the characteristics of miniaturization, intelligence and multi-function.

What is the difference between a membrane switch and a mechanical switch?

The main differences between membrane switches and mechanical switches are in terms of structure, performance, life, volume and weight.

Structure and working principle: The membrane switch consists of four parts: panel, upper circuit, isolation layer, and lower circuit. When the membrane switch is pressed, the upper circuit and the lower circuit are connected, and the circuit is disconnected when the finger is released, triggering a signal. The mechanical switch closes or disconnects the circuit through physical contact.

Lifespan: The working life of the membrane switch is dozens of times that of the ordinary mechanical switch, which can reach more than 10,000 times, while the lifespan of the traditional mechanical switch is at most 100,000-200,000 times.

Sealing: The membrane switch has good sealing and adapts to harsh environments, such as dustproof, explosion-proof, and anti-corrosion of harmful gases, while the mechanical switch is prone to failure in these environments.

Waterproof and dustproof: The membrane switch has the characteristics of waterproof, dustproof, and oil-proof, and can work stably in harsh environments, while the mechanical switch is easily affected in these environments.

Conductive performance: The conductive layer of the membrane switch can be printed with carbon paste, silver paste, etc., with excellent conductivity, and can accept high-voltage electric shock without damaging its function.

Volume and weight: The membrane switch is small in size and light in weight, with a total thickness of generally between 1.0 and 1.5 mm, which is suitable for applications with limited space.

Design flexibility: Due to its small size and light weight, the membrane switch is more flexible in design, and more buttons can be designed without taking up too much space.

As a new type of electronic component, the membrane switch panel has the characteristics of being thin, soft, waterproof and dustproof, and has been widely used in electronic equipment, household appliances and other fields. BEST Technology has advanced production technology and rich experience, and can accurately control the selection and processing of each layer of materials. Choosing BEST will get the best quality products.