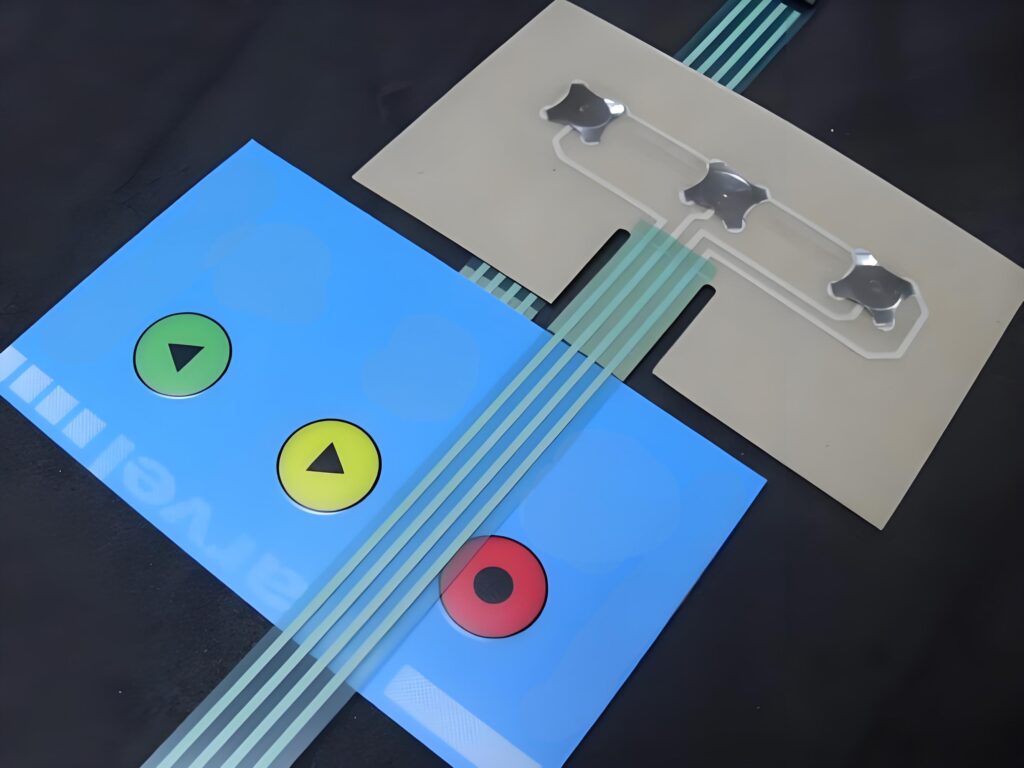

Membrane keyboards are a common input device and are widely used in various electronic products, such as computers, mobile phones, and remote controls. As a key component in membrane keyboards, metal dome plays a vital role in the performance and feel of membrane keyboards.

When were membrane keyboards made?

The development of membrane keyboards can be traced back to the 1970s. With the rise of personal computers, membrane keyboards gradually became popular. This type of keyboard uses a layer of membrane to realize the key function. Although it has a poor feel and is prone to failure, it marks the birth of membrane keyboard technology.

Compared with mechanical keyboards, membrane keyboards have the advantages of simple structure, low cost, and strong durability. With the advancement of technology, the feel and reliability of membrane keyboards have gradually improved.

How are membrane keyboards made?

The manufacturing process of membrane keyboards mainly includes the following steps:

Panel layer production: The panel layer is usually made of colorless and light-transmitting sheets such as PET and PC, and exquisite patterns and text are printed on the sheet through silk screen printing. The main function of the panel layer is identification and key.

Surface adhesive layer production: The main function of the surface adhesive layer is to tightly connect the panel layer with the circuit layer to achieve the effect of sealing and connection. The thickness of the surface adhesive is generally between 0.05 and 0.15 mm, with high viscosity and anti-aging properties.

Control circuit upper and lower layer production: These two layers use polyester film (PET) as a carrier, and a special process is used to screen-print conductive silver paste and conductive carbon paste on it to make it conductive. The common thickness is 0.125 mm.

Interlayer production: The interlayer is located between the upper circuit and the lower circuit layer, which plays a role in sealing and connection. The interlayer generally uses PET double-sided adhesive with a thickness of 0.05 to 0.2 mm.

Back adhesive layer production: The material selection of the back adhesive layer is closely related to the material of the membrane switch. Commonly used back adhesive materials include ordinary double-sided adhesive, 3M adhesive and waterproof adhesive.

What are the different types of membrane keyboards?

There are mainly the following types of membrane keyboards:

Crater structure: This is the most common membrane keyboard structure. The keycap and guide column are formed in one piece, and the keycap is in direct contact with the rubber membrane. The advantages of this structure are simple mold, low cost, certain waterproof performance, and easy maintenance.

Scissor foot structure: This structure separates the keycap and guide column, and two sets of connecting rod structure support frames are used between the keycap and the rubber membrane, which are shaped like scissors or “X”. The feel is relatively stable, but the production cost is high.

Palace column structure: This structure is designed to improve the shortcomings of the crater structure and the scissor foot structure. The keycap and guide column of the palace column structure are separated, and the keycap is in contact with the rubber membrane through elastic material, which has a relatively stable feel and is not easy to wear and age.

What is the lifespan of a membrane keyboard?

The service life of a membrane keyboard is usually around 3 million times. Over time, the silicone bowl inside the keyboard will age, resulting in problems such as the key rebound feel slipping or the key jamming.

Factors affecting the life of a membrane keyboard include:

Material: Membrane keyboards are usually made of plastic material, which will gradually age after long-term use, affecting the feel and life of the keyboard.

Keycap material: Keycaps of different materials have different wear resistance. Keycaps with high wear resistance can extend the service life of the keyboard.

Workmanship: The workmanship of the keyboard will also affect its life. Fine workmanship can reduce key wear and extend the service life.

What is the disadvantage of membrane keyboard?

First, the feel of the membrane keyboard will deteriorate over time. After long-term use, the keycaps will glow and slip, affecting the feel.

Second, there is a key position conflict problem with membrane keyboards. Due to the structural design of membrane keyboards, the service life of the keys is short, and key position conflicts are prone to occur in complex operations, affecting the user experience.

Third, the life of membrane keyboards is relatively short. Compared with mechanical keyboards, membrane keyboards have a shorter key life, and keys usually fail after long-term use.

In addition, the feel feedback of membrane keyboards is low. Since there are no separate moving parts, the tactile feedback is poor, which makes error-free and blind typing more difficult.

Finally, membrane keyboards are not suitable for high-frequency use scenarios. The circuits of membrane keyboards are interconnected. Once there is a problem with part of the circuit, the entire row of keys may become unusable.

Are membrane keyboards cheap?

The price of membrane keyboards is relatively low. The price advantage of membrane keyboards makes it attractive in terms of cost performance, especially in the past, when the price advantage of membrane keyboards was more obvious.

However, with the popularity of mechanical keyboards, the cost performance of membrane keyboards has shrunk significantly. The life of mechanical keyboards is between 50 million and 60 million times, while the life of membrane keyboard keys is only 300,000 to 1 million times. In addition, mechanical keyboards are also superior to membrane keyboards in terms of craftsmanship, feel, performance and experience.

Which is better, a mechanical or membrane keyboard?

1. Office environment

Membrane keyboard: suitable for use in a quiet office environment or when frequent business trips are required. The membrane keyboard keys make less sound, are light and easy to carry, and are suitable for use in libraries or office environments that need to be kept quiet.

Mechanical keyboard: suitable for use in fixed places, especially for work that requires long-term typing. Mechanical keyboards have a solid feel and clear feedback, suitable for users who have high requirements for typing experience.

2. Usage requirements

Membrane keyboard: low price, easy to carry, suitable for users with limited budgets or who need to move frequently. Wireless membrane keyboards are more convenient to carry, suitable for business trips or mobile offices.

Mechanical keyboards: They are expensive, heavy, and not suitable for frequent movement. However, they have a long service life, up to millions of keystrokes, and are suitable for users who need to type for a long time or have high requirements for keyboard life.

As a key component in membrane keyboards, metal domes play a vital role in the performance of membrane keyboards. Only by selecting the appropriate type of metal domes and accurately assembling and debugging them with the membrane circuit can a membrane keyboard with good performance be produced.