A capacitance switch is a switch that uses the principle of capacitance to achieve touch operation. It triggers the switch action by detecting the change in capacitance between the human body or other conductive objects and the switch. It does not require traditional mechanical buttons and has the advantages of sensitive operation, simple appearance, and long life.

What is a capacitor switch?

A capacitor switch is a highly intelligent level measurement product. Its principle is to use advanced radio frequency capacitance technology to measure the level through the change in plate capacitance and has the function of an alarm switch. Capacitance switches come in many forms, including single-point, double-point, three-point, and four-point.

The working principle of a capacitor switch is based on the change in capacitance. It usually consists of a pair of adjacent electrodes. When a conductor (such as a finger) approaches the electrode, a coupling capacitor is generated between the electrode and the conductor. Detecting the change in this capacitance can determine whether an object is approaching, thereby controlling the switch on and off.

Capacitance switches are widely used in various scenarios that require level measurement, such as industrial automation, warehouse management, and other fields. Its intelligence and high precision make it particularly important in systems that require precise control.

With the development of science and technology, capacitive switches are also constantly improving, combining more intelligent functions, making them more widely used in modern industry and home automation.

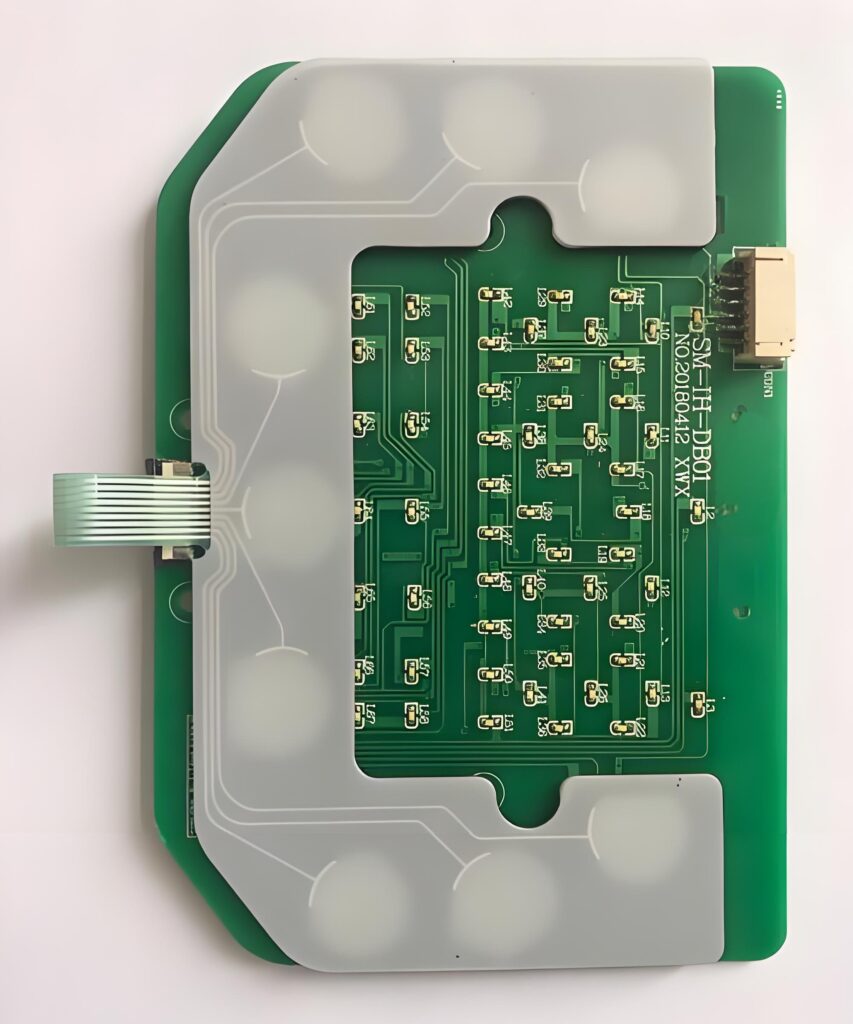

How are capacitive switches composed?

Electrodes: usually conductive patterns printed on PCB boards, or transparent conductive coatings embedded under glass or plastic surfaces (such as ITO, indium tin oxide).

Insulation layer: located on the electrodes, preventing direct electrical contact while allowing the electric field to pass through.

Control circuit: responsible for monitoring capacitance changes and performing corresponding logical operations based on the changes.

Power supply: powering the entire system.

What is the function of a capacitive switch?

The main function of a capacitive switch is to perform level measurement and alarm switch control. It uses advanced radio frequency capacitance technology to determine the level through changes in plate capacitance and has the function of an alarm switch.

Capacitive switches can detect solid particles, powders and liquids (including conductive and non-conductive media), especially for highly corrosive media, and can overcome the effects of the adhesion layer on the probe and material splashing on the measurement to ensure the accuracy of the measurement.

How does a capacitance switch work?

At its core, a capacitance switch is a simple capacitor consisting of two parallel conductive plates (electrodes) separated by an insulating material (dielectric). When no object is close to it, the capacitor has a fixed capacitance.

When a finger or other conductive object approaches or touches one of the electrodes, it changes the electric field distribution of the capacitor, thereby increasing the effective area of ??the capacitor or reducing the distance between the electrodes, causing the capacitance value to change.

This change in capacitance is converted into an electrical signal and processed by a specialized circuit (such as a microcontroller). The circuit can detect small changes in capacitance and determine whether a touch action has occurred.

Once the change in capacitance exceeds a preset threshold, the circuit triggers the corresponding action, such as lighting up the screen, turning on the device, or performing a function.

What does a capacitor switch do?

Capacitor switches play an important role in modern electronic devices and home appliances. Their main functions can be summarized as follows:

1. Touch input

The most direct function of a capacitor switch is to provide a touch input method without mechanical contact. Users can control the device by touching the screen or buttons without applying physical pressure. This approach not only improves the user experience, but also extends the life of the device.

2. Friendly interface

Capacitive switches can be designed in various shapes and sizes, seamlessly blending with the device’s exterior design, making the device look more concise and modern. In addition, the touch interface can dynamically display different functions, providing a richer interactive experience.

3. Durability

Since capacitive switches have no mechanical parts and will not wear out due to repeated pressing, they have high durability. This makes them particularly suitable for applications in frequently used scenarios, such as mobile phones, tablets, and household appliances.

4. Waterproof and dustproof

Capacitive switches can be designed with a completely sealed structure to prevent moisture and dust from entering the interior of the device, improving the reliability and safety of the device. This is especially important in humid environments such as kitchens and bathrooms.

5. Energy saving

Capacitive switches can be in a low-power state when not touched, and only activate the relevant circuit when a touch action is detected, thereby saving energy. This is especially beneficial for battery-powered devices.

6. Versatility

Capacitive switches can be programmed with software to implement multiple functions, such as single click, double click, long press, and other different touch gestures, thereby achieving more control options. This flexibility makes the device more functional and diverse.

7. Safety and hygiene

In industries such as medical and food processing, the contactless nature of capacitive switches can reduce the spread of bacteria and viruses and improve hygiene levels. In addition, they can also be used for remote control in hazardous environments to reduce the risk of operators.

8. Aesthetics

Capacitive switches can be designed to be transparent or translucent, blending with the surface material of the device to provide better visual effects. This is especially important for the design of high-end electronic products and household appliances.

9. Strong adaptability

Capacitive switches can adapt to different environments and conditions, such as high temperature, low temperature, high humidity, etc., and have good environmental adaptability. This allows them to work stably in various application scenarios.

10. Customization

Capacitive switches can be customized according to different needs, including shape, size, sensitivity and function, to meet the requirements of specific applications.

In short, capacitive switches have become an indispensable part of modern electronic devices through their unique touch technology and multiple advantages, greatly improving the user experience and the overall performance of the device.

How do you test a capacitor switch?

Appearance inspection: Check the surface of the capacitor switch for scratches, cracks, or other physical damage.

Installation inspection: Make sure the switch is firmly installed and not loose or misplaced.

Single touch: Gently touch different areas of the switch with your finger to check whether it can trigger the response correctly.

Multi-touch: If multi-touch is supported, test the response when multiple fingers touch at the same time.

Continuous touch: Touch the switch for a period of time to check whether it can maintain the response continuously.

What is capacitive switch vs mechanical switch?

1. Working principle

Capacitive switches recognize touch actions by detecting changes in capacitance value. When a finger or other conductive object approaches or touches the electrode, the capacitance value changes, which is detected by the circuit and converted into a control signal.

Mechanical switches close or open the circuit through physical contact. When the switch is pressed, the metal contacts inside touch or separate, changing the state of the circuit.

2. Structure

Capacitive switches usually consist of conductive electrodes, insulating layers, and control circuits. The electrodes can be conductive patterns printed on a PCB or transparent conductive coatings embedded in materials such as glass and plastic. There are no movable mechanical parts, so the structure is simpler.

Mechanical switches contain multiple mechanical parts, such as buttons, springs, contacts, etc. These parts need to be assembled precisely to ensure reliable mechanical action. There are movable mechanical parts, which require regular maintenance and inspection.

3. Performance

Capacitive switches can detect slight touch actions and work even when wearing gloves; there is no mechanical wear and tear, and theoretically, they can be touched an unlimited number of times; they can be designed as sealed structures to prevent moisture and dust from entering; they can be in a low-power state when not touched, saving energy.

Mechanical switches are usually very reliable under proper maintenance, but may wear out under frequent use; due to the wear of mechanical parts, the life of mechanical switches is usually limited and may need to be replaced regularly; special sealing designs are required to achieve waterproof and dustproof functions; in some cases, mechanical switches may need to be continuously powered to maintain their state.

As a new type of touch technology, capacitive switches have been widely used in various fields. With the continuous advancement of science and technology and the continuous growth of market demand, capacitive switches are also constantly developing and innovating, and there will be broader application prospects in the future.