Tactile is a crucial way of perception. Dome can define tactile by its sensitive response to pressure. When we touch an object, we apply a certain amount of pressure to it. If the object contains dome, the dome will deform to varying degrees depending on the amount of pressure.

How to define touch?

The feeling produced by the skin tactile receptors contacting mechanical stimulation

Tactile refers to the feeling produced by the skin tactile receptors contacting mechanical stimulation. Tactile includes mechanical stimulation such as contact, sliding, and pressure. These stimulations are converted into electrical signals by the tactile receptors on the surface of the skin and transmitted to the brain through the nervous system for processing.

Tactile dome has good elasticity. When pressed, it will deform and then quickly rebound to its original shape. This rebound force will give the operator’s fingers a reaction force, forming a clear tactile feeling, allowing the operator to clearly feel the process of the key being pressed and bounced.

In some cases, the tactile dome makes a slight “click” sound when pressed, which, combined with the sense of touch, further enhances the operator’s tactile experience. The sound is caused by the movement of the tactile dome and the collision or friction with other components.

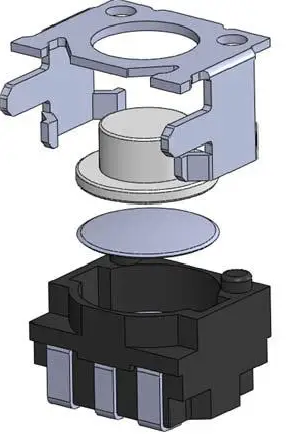

What is a tactile dome?

A tactile dome, also known as a key dome or pot dome, is a switch component used to provide tactile feedback. It is usually made of stainless steel 301 or 304 material and has the characteristics of ultra-thin (0.05mm-0.1mm thickness) and ultra-thick (high hardness).

It usually has a certain elastic deformation ability. The dome can deform when subjected to external force and can quickly return to its original shape after the external force disappears. Some tactile domes are in a convex state when not pressed, and they will be concave when pressed, and return to a convex state after the pressing ends.

How does a tactile dome work?

The working principle of the tactile dome is mainly based on its elastic deformation and recovery characteristics to achieve tactile feedback. When the tactile dome is subjected to external pressure, the structure of the dome will undergo elastic deformation.

In the application scenario of mobile phone buttons, when the user presses the button, the tactile dome under the button will be subjected to vertical pressure. According to the structural design of the dome, different deformation modes such as bending and compression may be presented. For example, the top of the tactile dome with a common arched structure will be concave when pressed.

This deformation occurs within the elastic range of the dome material, which means that the dome can return to its original shape after the pressure disappears.

What are the materials used to make tactile dome?

The materials used to make tactile dome mainly include stainless steel, beryllium copper, manganese material, etc. Stainless steel is one of the most commonly used materials, and specific models such as 301 or 304 stainless steel have the characteristics of ultra-thin (0.05mm-0.1mm thickness) and ultra-thick (high hardness).

Beryllium copper, spring steel, brass, etc. are also common metal materials. Tactile dome made of these materials can deform when subjected to external force and quickly return to its original shape after the external force is removed.

Characteristics of different materials:

Stainless steel: has high toughness and good hardness, suitable for application scenarios requiring high strength and corrosion resistance.

Beryllium copper: has good elasticity and conductivity, suitable for electronic components requiring high elasticity and conductivity.

Manganese material: has good conductivity and stability after heat treatment, suitable for switch components.

What are the common shapes of tactile dome?

Common shapes of tactile dome include circular, cross, triangular and elliptical. Tactile dome of these shapes are widely used in electronic devices, such as membrane switches, contact switches, PCB boards, FPC boards and medical devices.

Application scenarios of different shapes:

Circular tactile dome: widely used in various electronic devices because it is simple and easy to manufacture.

Cross-shaped tactile dome: often used in occasions where a specific contact distribution is required, such as certain specific switch designs.

Triangular tactile dome: Suitable for contact designs that require a specific angle or shape.

Oval tactile dome: Provides a larger contact area and is suitable for occasions that require greater pressure distribution.

Size range of different shapes:

The size range of tactile dome ranges from 3mm to 20mm in diameter and the force ranges from 100g to 600gf. These size and force selections can be adjusted according to specific application requirements.

What are the applications of tactile dome?

Tactile dome is widely used in many fields, mainly including the following aspects:

Membrane switches and contact switches: Tactile dome is an important component in membrane switches and contact switches, using its conductivity and stable rebound force to provide high-quality tactile feedback.

PCB boards and FPC boards: In printed circuit boards (PCBs) and flexible circuit boards (FPCs), tactile dome is used to achieve electrical connection and disconnection functions.

Medical devices: Tactile dome is also widely used in medical devices to ensure precise operation of the equipment and reliable electrical connection.

As a common mechanical component, dome is redefining tactile in a unique way. Through pressure sensing, vibration feedback and shape change, it plays an important role in many fields such as electronic devices, medical fields and automobile manufacturing.