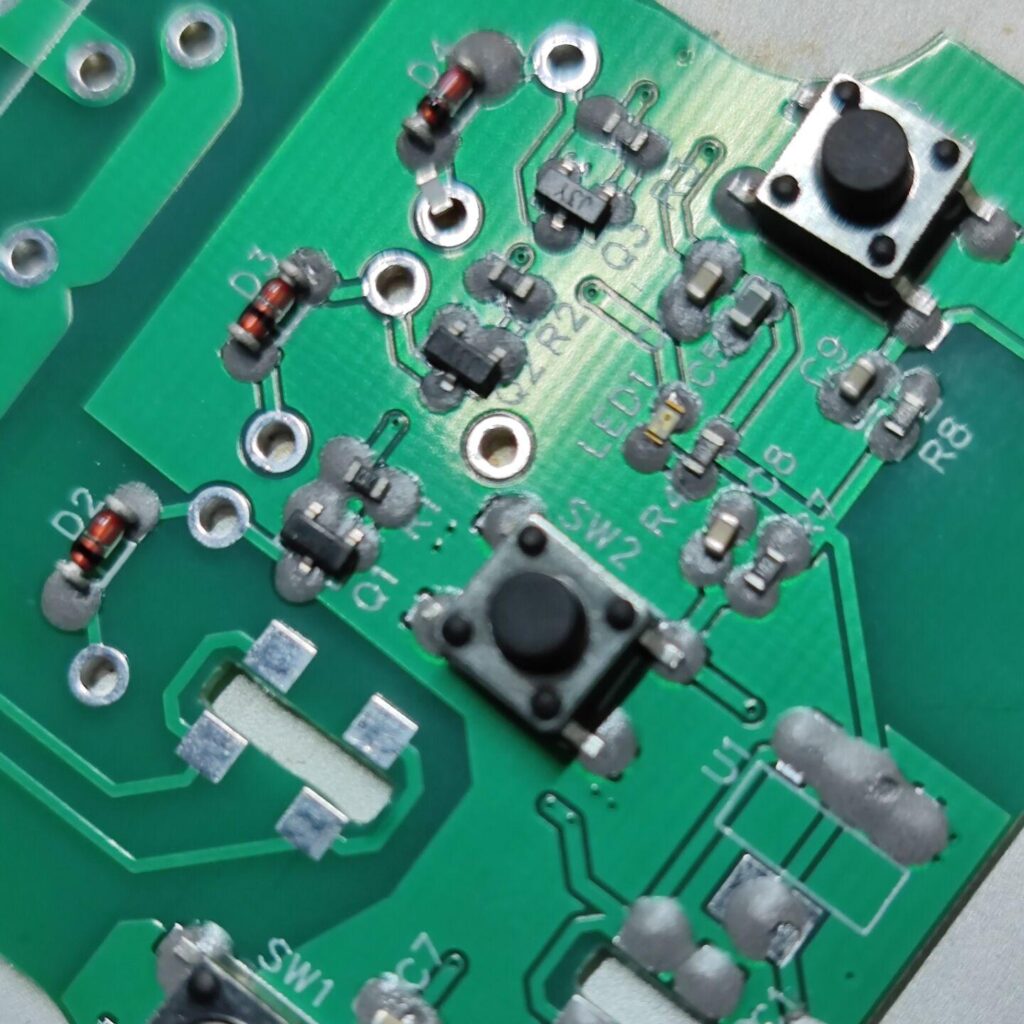

A micro SMD switch is a small switch that is mounted on a circuit board using surface mount technology. The size of a micro SMD switch is usually very small, which allows for high-density circuit layout in a limited space. This is essential for the design trend of modern electronic products that pursue thinness and miniaturization.

What does SMD mean in switches?

SMD is the abbreviation of surface mount device, which means surface mount device. It is one of the SMT (surface mount technology) components. In the early stages of electronic circuit board production, through-hole assembly was done entirely manually.

After the first batch of automated machines were launched, they could place some simple pin components, but complex components still needed to be placed manually before reflow soldering. Surface mount components mainly include rectangular chip components, cylindrical chip components, composite chip components, and special-shaped chip components.

Specifically, an SMD tact switch is a tact switch that can be directly operated by an SMT placement machine, and has its own advantages and disadvantages compared to a DIP pin tact switch. DIP pin tact switches need to be inserted into the circuit board for soldering, while SMD tact switches can be directly operated by SMT placement machines.

Where are micro switches commonly used?

Micro switches are commonly used to control the switching operation of electronic devices, such as controlling power switches, keyboard switches, relay switches inside devices, etc. It can also be used to detect real-time detection phenomena such as magnetic fields, temperature, light, humidity, etc., so as to achieve accurate control of automatic control systems and sensors.

Specific application scenarios of micro switches include:

Smart home: In the field of smart home, micro switches can be used to control the switching operation of household appliances and improve the level of intelligence of the home.

Automotive electronics: In automobiles, micro switches are used to control windows, doors, wipers, etc. to ensure the normal operation of the vehicle.

Industrial automation: In industrial automation systems, micro switches are used to achieve accurate control and monitoring and improve production efficiency.

Medical equipment: In medical equipment, micro switches are used to control precision instruments and medical devices to ensure the stability and accuracy of the equipment.

What is the advantage of micro switch?

The core advantage of micro switch lies in its small size and compact structure, as well as high precision, fast response and wide range of applications.

The main advantages of micro switch include:

Small size: Micro switch has a small contact spacing and a snap-action mechanism, which is very compact in design and flexible in operation.

High precision: The snap-action mechanism of the micro switch can ensure that the contacts can switch to the same position even in repeated on/off operations, with small position detection error, which is suitable for application scenarios with high precision requirements.

Fast response: Through the external mechanical force acting on the metal shrapnel, the micro switch can achieve fast on/off action and fast response speed, which is suitable for occasions requiring fast response.

Rich functions: Micro switch has various types and can be designed and selected according to different application scenarios. The actuator shapes include straight rods, bent rods, balls, sliders, rollers, shrapnel and other forms to meet the requirements of control operations in different parts.

Wide range of applications: Micro switch is widely used in various electrical appliances, machinery, communications, digital audio and video, and electronic products.

What is the durability of a micro switch?

Micro switches are usually very durable and can withstand millions of opening and closing operations. Metal dome switches are extremely durable and can last for millions of opening and closing operations.

The durability of micro switches is mainly due to their design and manufacturing process. This design not only reduces the need for costly maintenance or replacement, but also makes the switch perform well in demanding applications.

How long do micro switches last?

The service life of a micro switch depends on its type and specific model, and generally ranges from tens of thousands to tens of millions of times.

The service life of a micro switch can be divided into mechanical life and electrical life. Mechanical life refers to the number of times the switch is operated without power, while electrical life refers to the service life of the switch when power is supplied. Different types of micro switches have different life ranges.

Switches using stainless steel domes can have a life of more than 2 million times. The mechanical and electrical life of micro switches also vary, with mechanical life generally being higher and electrical life possibly being lower.

Factors that affect the service life of a micro switch include the use environment, frequency of operation, and maintenance. Frequent operation and humidity, temperature and other factors in the use environment will affect the life of the switch. In addition, choosing the right material and design can also significantly improve the durability of the switch.

Why do micro switches have three pins?

The reason why a micro switch has three pins is because it usually has two contact forms: normally open and normally closed. The normally open contact is open when the switch is not activated, while the normally closed contact is closed when the switch is not activated.

Specifically, the three pins of the micro switch correspond to:

Common terminal (C): This is the common connection point of the switch circuit and is connected to the other two terminals.

Normally open terminal (NO): This terminal is open when the switch is not activated and is only connected when the switch is pressed.

Normally closed terminal (NC): This terminal is closed when the switch is not activated and is only disconnected when the switch is pressed.

This design makes micro switches very useful in many applications, such as scenarios where it is necessary to monitor the change of switch state and keep the circuit connected at the same time.

In addition, the combination of normally open and normally closed contacts provides more circuit control options, making micro switches an indispensable component in many electronic devices.

What is the difference between a micro switch and a normal switch?

The main differences between micro switches and normal switches are their design, function and application scenarios. Micro switches are usually smaller in size and faster in response, suitable for applications requiring high sensitivity, while normal switches are more suitable for general circuit control needs.

Micro switches are more compact in design and are usually used in applications requiring high sensitivity. They use a small force to trigger the switch action, have a small contact spacing and a snap-action mechanism. In contrast, normal switches do not have these special designs and are mainly used for general circuit control and disconnection.

In terms of function, micro switches are often used in devices requiring high sensitivity due to their fast response characteristics, such as keys of electronic devices and control buttons of remote controls. They can provide a better user experience and adapt to the needs of various application scenarios. Normal switches are mainly used for basic circuit control without special functional requirements.

In general, micro switches occupy an important position in the high-tech field with their compact design and high sensitivity, while ordinary switches meet basic circuit control needs and are suitable for a wider range of scenarios.

As an important component in the electronics field, micro SMD switches provide important support for the functional realization of electronic equipment with their small size, excellent performance and wide application. When selecting and using micro SMD switches, it is necessary to select appropriate switches according to actual application requirements and pay attention to the correct installation method and operation method.