A metal dome switch is a switch device that uses a metal dome as a core component to control the on/off of a circuit. It is usually composed of a metal dome, a contact point, a housing, and a connection terminal. Metal domes usually have a certain elasticity and recovery force, can deform when subjected to external force, and quickly return to their original shape after the external force disappears.

What is a dome switch?

A metal dome is an elastic, thin-sheet component made of metal materials (such as stainless steel, beryllium copper, spring steel, brass, etc.). It usually has a specific shape and size, can deform when subjected to external force, and quickly return to its original shape after the external force is removed.

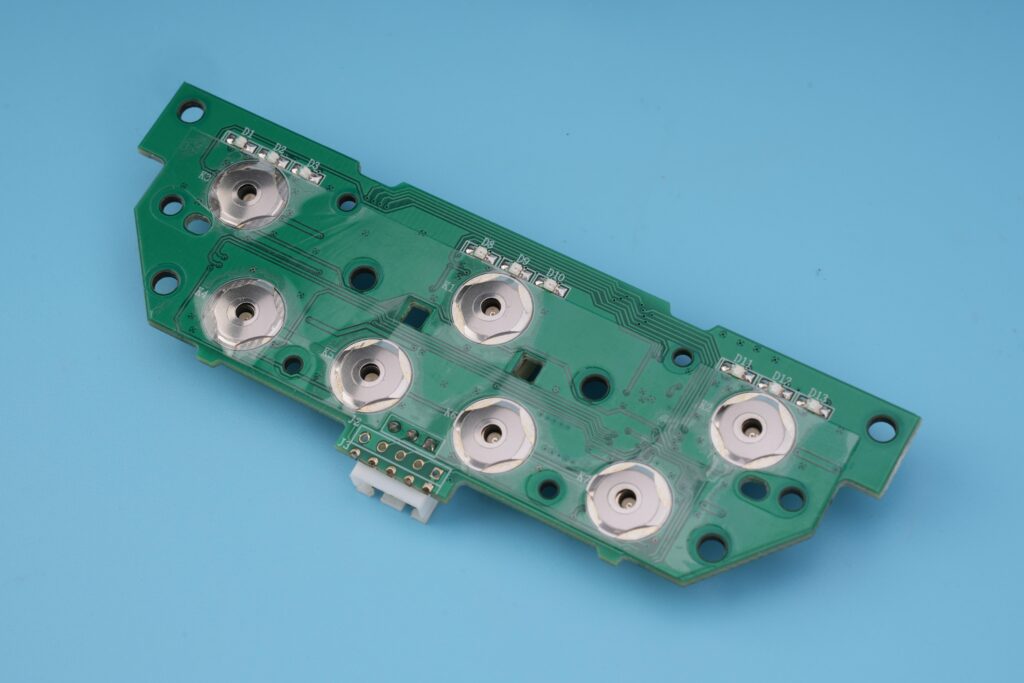

Metal domes are mainly used in membrane switches, contact switches, PCB boards, FPC boards, and medical devices. Through its conductivity and stable resilience, it plays a high-quality switch role between the operator and the product, while providing tactile feedback.

The working principle of the metal dome is based on its elastic properties. When pressed, the center point of the dome is concave and contacts the circuit on the PCB, thus forming a loop, the current passes through, and the product can work normally.

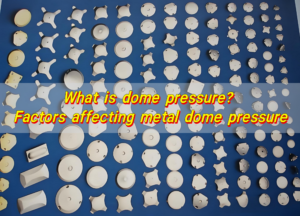

Metal domes have various shapes and specifications, the most common ones are round, cross, triangle, oval, etc., with diameters ranging from 3mm to 20mm. According to different application requirements, metal domes can also be surface treated, such as nickel plating, silver plating, gold plating, etc., to adapt to different environments and functional requirements.

What is a dome used for?

The metal dome switch is an electronic switch that mainly realizes the on and off of the circuit through the deformation of the metal dome. It has the characteristics of small size, good conductivity, good feel, long life, easy assembly, dustproof, waterproof, oil-proof, etc., and is widely used in various electronic products.

The specific applications of metal dome switches include:

1. Electronic products: such as car navigation systems, remote controls, MP3 players, etc.

2. Communication equipment: such as mobile phones, cordless phones, mother-and-child machines, walkie-talkies, etc.

3. Medical equipment: using its stable rebound force and long life to provide reliable switching functions.

The advantages of metal dome switches include:

1. Long life: metal domes have good wear resistance and resilience, ensuring long-term and stable use of the switch.

2. High reliability: with good dustproof, waterproof and oil-proof properties, suitable for various harsh environments.

3. Good feel: the rebound force of the metal dome is uniform, providing good tactile feedback.

In summary, metal dome switches play an important role in various electronic devices due to their unique structure and excellent performance, providing reliable and efficient switching functions.

What does a metal dome switch consist of?

1. Metal dome: usually made of materials with good elasticity and conductivity such as stainless steel and copper. The spring is generally in an arched or other specific shape. Its design allows it to remain separated from the contact point of the circuit when it is not under force, but can deform and contact the contact point when subjected to a certain external force, thereby conducting the circuit.

2. Contact point: Generally located under or around the spring, usually made of conductive materials, such as metal contacts or conductive rubber. When the spring is deformed, it contacts the contact point to achieve circuit conduction.

3. Shell: used to protect the internal spring and contact point, while providing a mounting and fixing structure. The shell material can be plastic, metal, etc., with certain strength and insulation properties.

4. Pin or connection terminal: used to connect the spring switch to the external circuit. The pin can be a metal pin welded on the circuit board, or it can be a terminal connected to the external circuit by means of a plug-in.

What is the working principle of metal dome switch?

When an external force acts on the spring switch, the spring deforms elastically, bends or moves toward the contact point, and contacts the contact point, thereby conducting the circuit. When the external force disappears, the dome returns to its original shape by its own elasticity, separates from the contact point, and the circuit is disconnected.

This working principle makes the dome switch have fast response, reliable on-off performance and certain tactile feedback. When operating, the user can control the on-off of the circuit by pressing or releasing the dome switch, and can feel obvious tactile feedback, which enhances the certainty of the operation.

What are the different metal dome shapes?

Metal domes have many different shapes, mainly including circular, cross, triangular and elliptical.

1. Circular metal domes are the most common shape, with diameters ranging from 3mm to 20mm.

2. Cross-shaped metal domes are also called quadrilaterals, which are often used in situations where stable contact is required.

3. Triangular metal domes can also provide stable contact performance in specific applications.

4. Elliptical metal domes have better adaptability and stability, and are suitable for some special application scenarios.

What is the difference between membrane and dome switch?

The main difference between membrane switches and dome switches lies in their working principles and application scenarios. Membrane switch is an operating system that integrates key functions, indicating elements, and instrument panels. It consists of four parts: panel, upper circuit, isolation layer, and lower circuit. When the membrane switch is pressed, the contact of the upper circuit deforms downward and contacts the plate of the lower circuit for conduction. After the finger is released, the contact of the upper circuit rebounds, the circuit is disconnected, and the loop triggers a signal.

Shrapnel switch, especially metal shrapnel switch, is a switch that uses metal shrapnel as a conducting medium. Metal shrapnel switch has the characteristics of small size, good conduction, good feel, long life, easy assembly, and good dustproof. It is mainly used in electronic products, such as car navigation systems, remote controls, mobile phone buttons, etc.

As the only metal component in the membrane switch, the metal shrapnel has the advantages of strong conductivity, stable rebound, and good feel. The metal shrapnel switch has a wide operating temperature range, which can reach -20 to 80, and is waterproof, dustproof, and oilproof.

The membrane switch realizes the switching function through the interaction of the panel, upper circuit, isolation layer and lower circuit, while the shrapnel switch relies on the elastic deformation of the metal shrapnel to realize conduction and disconnection. In addition, the membrane switch has a wider range of applications and can be used in various electronic devices, while the shrapnel switch is more used in occasions that require high precision and high reliability, such as mobile phone buttons.

Conclusion:

In short, the metal shrapnel switch plays an important role in many fields such as consumer electronics, automotive electronics, industrial control, and medical equipment with its unique structure and performance. It has become an indispensable part of electronic equipment with its good feel, high reliability, fast response and miniaturized design.