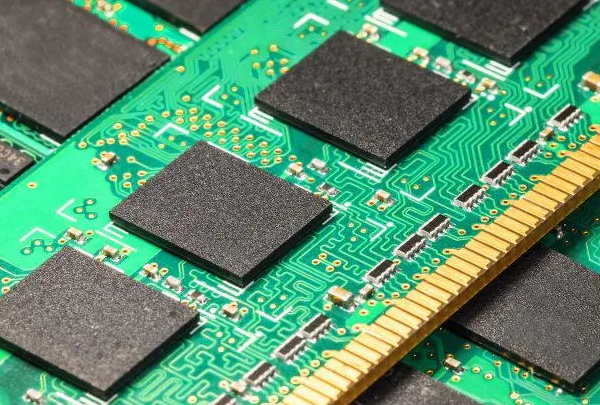

SMD surface mount device is a technology that directly mounts electronic components on the surface of a printed circuit board (PCB). SMD covers many types of electronic components, such as resistors, capacitors, integrated circuits, diodes, transistors, etc. These components are fixed on the surface of the PCB by welding and other methods, without the need to punch holes on the PCB like traditional through-hole mounting technology.

What is a surface-mount component?

Surface mount components (SMC) are electronic components without pins or short leads, which are mounted on the surface of a printed circuit board (PCB) or other substrates by surface mount technology (SMT), and assembled by soldering by reflow soldering or dip soldering.

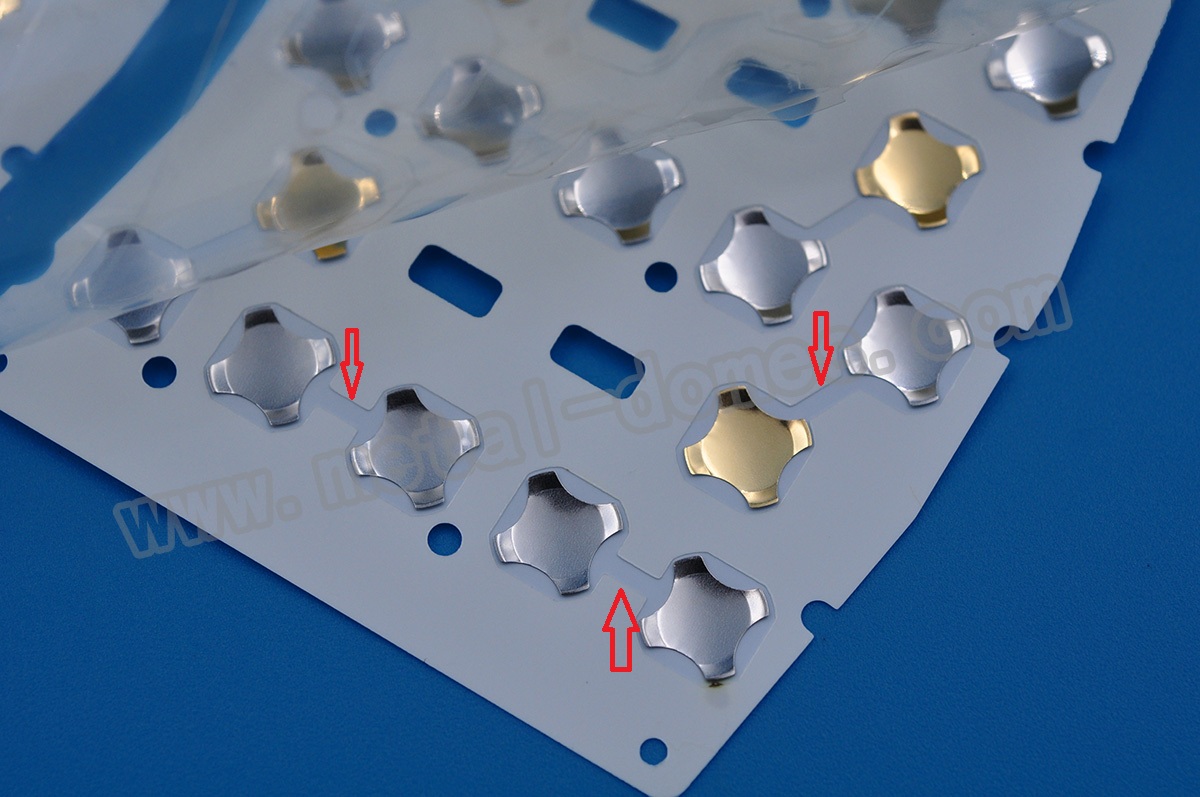

The main feature of surface mount components is their design without pins or short leads, which enables them to be mounted on PCBs in a high-density manner, thereby reducing the volume and weight of electronic products and improving assembly efficiency and reliability.

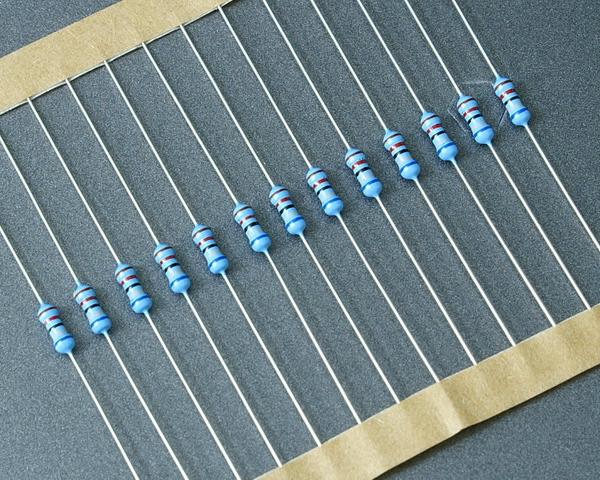

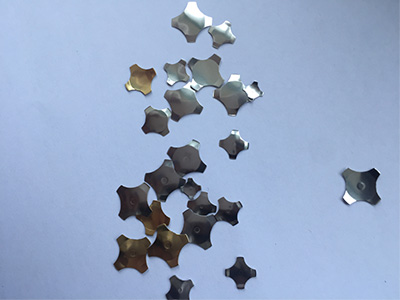

Surface mount components can be divided into rectangular chip components, cylindrical chip components, composite chip components, and special-shaped chip components according to their structural shape. According to functional classification, surface mount components include passive components (SMC) and active devices (SMD), etc. Passive components include resistors, capacitors, etc., while active devices include transistors, integrated circuits, etc. ?

Why is Surface Mount Technology used?

The main reasons why surface mount technology (SMT) is widely used include: the pursuit of miniaturization of electronic products, the development of integrated circuits, the demand for production automation and mass production, and the development of electronic components.

First, the trend of miniaturization of electronic products is one of the main factors driving the use of SMT. With the advancement of technology, electronic products are increasingly pursuing miniaturization and lightweight. Traditional perforated plug-in components can no longer meet this demand, and surface mount technology can integrate more functions in a limited space, thereby promoting the development of electronic products in a smaller and lighter direction?.

Secondly, the development of integrated circuits is also an important reason for the use of SMT. Integrated circuits (ICs) are widely used in modern electronic products, and these integrated circuits are usually pinless surface mount devices (SMDs) that can only be assembled by SMT.

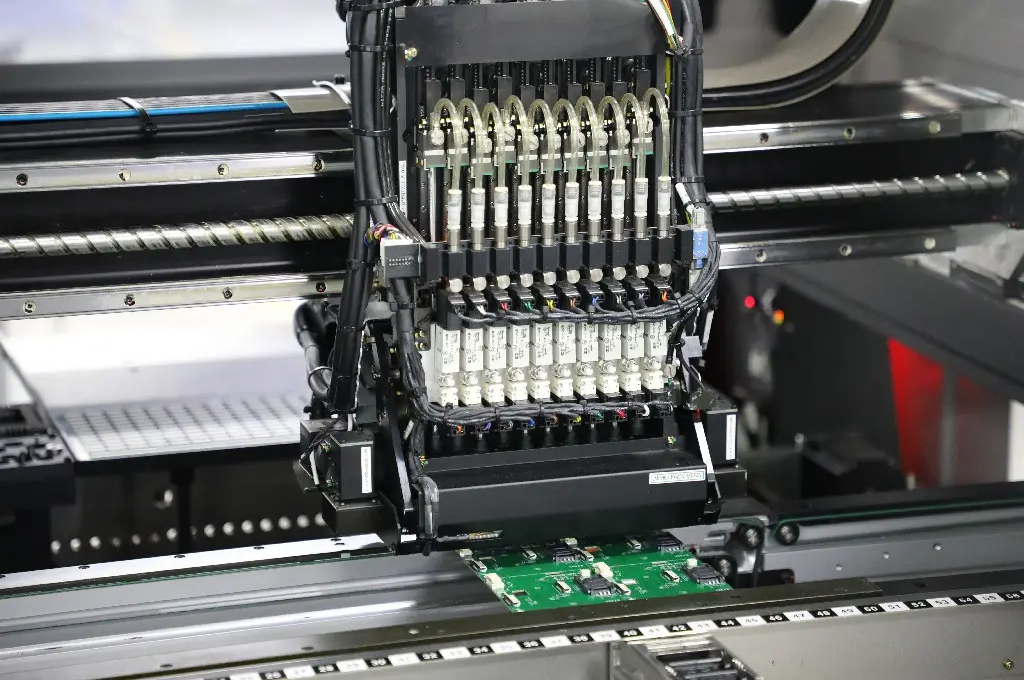

In addition, the demand for production automation and mass production is also one of the reasons why SMT is widely adopted. The SMT assembly process is highly automated, which can significantly reduce the labor cost of mass production. Through highly automated production processes, manufacturers can produce high-quality products at low cost and high yield, meet market demand and enhance market competitiveness.

Finally, the development of electronic components also supports the use of SMT. With the diversified application of semiconductor materials and the continuous advancement of electronic technology, new components and technologies are constantly emerging, all of which require SMT to achieve efficient assembly and production.

What is the difference between SMD and SMT?

The main difference between SMD and SMT is that they refer to different objects. SMD refers to surface mount devices, while SMT refers to surface mounting technology. ?

SMD is a surface mount device, which is an electronic component manufactured using a thin film process and can be directly mounted on the surface of a printed circuit board (PCB). SMD devices have the advantages of small size, light weight, and powerful functions, and are widely used in the design and production of electronic products.

In contrast, SMT (Surface Mount Technology) is a surface mounting technology, which is a technology for directly mounting electronic components on the surface of a PCB. SMT technology can achieve high-speed, high-precision, and high-density assembly, and is widely used in high-speed circuit boards, high-density circuit boards, and multi-layer circuit boards. ?

In terms of structure, SMT technology is to paste electronic components on the surface of PCB through solder balls or adhesives, while SMD is to solder electronic components directly on the surface of PCB. Since SMD devices can be directly soldered on the surface of PCB, the steps of pad design and production in the soldering process can be omitted, which improves production efficiency and reduces costs.

In terms of application, SMT technology is mainly used in fields such as high-speed circuit boards, high-density circuit boards and multi-layer circuit boards, while SMD devices are mainly used in consumer electronics, communication equipment, computers and other fields due to their small size, light weight and powerful functions.

In the manufacturing process, SMT requires the use of special equipment for printing, mounting and testing, while SMD manufacturing requires the use of special equipment for molding, cutting, packaging and other processes. Since SMD devices can be directly soldered on the surface of PCB, special treatment of PCB is required to ensure soldering quality and reliability.

In terms of maintenance, due to the high assembly density of SMT technology, regular cleaning and inspection are required, while SMD devices have relatively less maintenance work due to their simple structure and easy maintenance, but if a failure occurs, repairing or replacing SMD devices may be more difficult and time-consuming.

What is the difference between SMD and SMC?

SMD usually refers to specific electronic devices, such as resistors, capacitors, integrated circuits, etc., which are mounted on printed circuit boards using surface mount technology.

SMC is a broader concept that covers all surface mount components, including connectors, inductors and other special components in addition to common electronic devices.

SMD emphasizes the characteristics and specifications of the individual device itself and its surface mount.

SMC emphasizes the overall surface mount type of components, which is a more general concept.

What is the advantage of SMD?

The main advantages of SMD (surface mount device) include:

Small size and light weight: SMD components are small in size and light in weight, which can significantly reduce the substrate area occupied, achieve high-density integration, and are conducive to the design of miniaturized and lightweight electronic products.

Good electrical performance: SMD components have excellent electrical performance, especially in high-frequency performance, because their short pins and short connection paths help reduce inductance and resistance, thereby improving performance.

?Suitable for automated production?: SMD components are suitable for the production of automated patch machines, which improves production efficiency and quality stability, while also reducing production costs?.

?Good thermal performance?: SMD components are in direct contact with the PCB surface, which is conducive to heat dissipation and improves the thermal performance of the components?.

?Space saving?: Since SMD components are directly pasted on the PCB board and do not require drilling, space can be saved and the circuit board design can be more compact?.

?Easy to repair and maintain?: The surface mounting method of SMD components makes it more convenient to repair and replace components?.

?Increase production speed?: Automated assembly improves production efficiency, especially in large-scale batch production.

?Improve quality?: Automated assembly reduces human errors and improves the overall quality of the product?.

What is the function of the SMD?

The main functions of SMD (surface mount device) include storing energy, transmitting signals, filtering, and generating magnetic fields. ? These functions make SMD play an important role in various electronic circuits?.

Specifically, SMD inductors can store electrical energy and transfer it to other parts of the circuit, generate a magnetic field through the current, and release energy when the current stops, acting as a buffer to stabilize the current and voltage.

In communication and RF circuits, SMD inductors can also be used as signal transmission elements, changing the current or magnetic field to change the signal characteristics, and are used for functions such as demodulation, modulation, filtering, and frequency selection.

In addition to inductors, SMD also includes other types of devices, such as electrolytic capacitors, whose functions include storing charge, smoothing current, and filtering noise. Electrolytic capacitors have a wide operating temperature range, and a certain range of rated voltage and capacitance, which are suitable for different circuit requirements.

What are the most common SMD components?

The most common SMD components include resistors, capacitors, inductors, integrated circuits, etc. ? These components are widely used in electronic circuits because they have the advantages of small size, light weight, and high installation density.

Resistors: Resistors are one of the most common SMD components and are used to limit the flow of current in the circuit.

Capacitors: Capacitors are used in circuits to store and release electrical energy, similar to temporary batteries.

Inductor: Inductors store energy in a magnetic field when current flows through them. They play a role in filtering and suppressing electromagnetic interference in circuits.

Integrated Circuits: Integrated Circuits are a very important type of SMD components, containing multiple electronic components and circuit structures to achieve specific functions.

As an advanced electronic component installation technology, SMD has many advantages such as miniaturization, high-density packaging, automated production, good electrical performance and easy maintenance. In today’s era of rapid development of electronic technology, SMD has become one of the mainstream technologies for electronic equipment manufacturing.