As a unique electronic component, custom membrane switches are showing strong charm in many fields with their high customizability and excellent performance. It is no longer a standardized product in the traditional sense, but can be precisely customized according to different needs, bringing a new operating experience and visual experience to electronic devices.

What is a membrane switch?

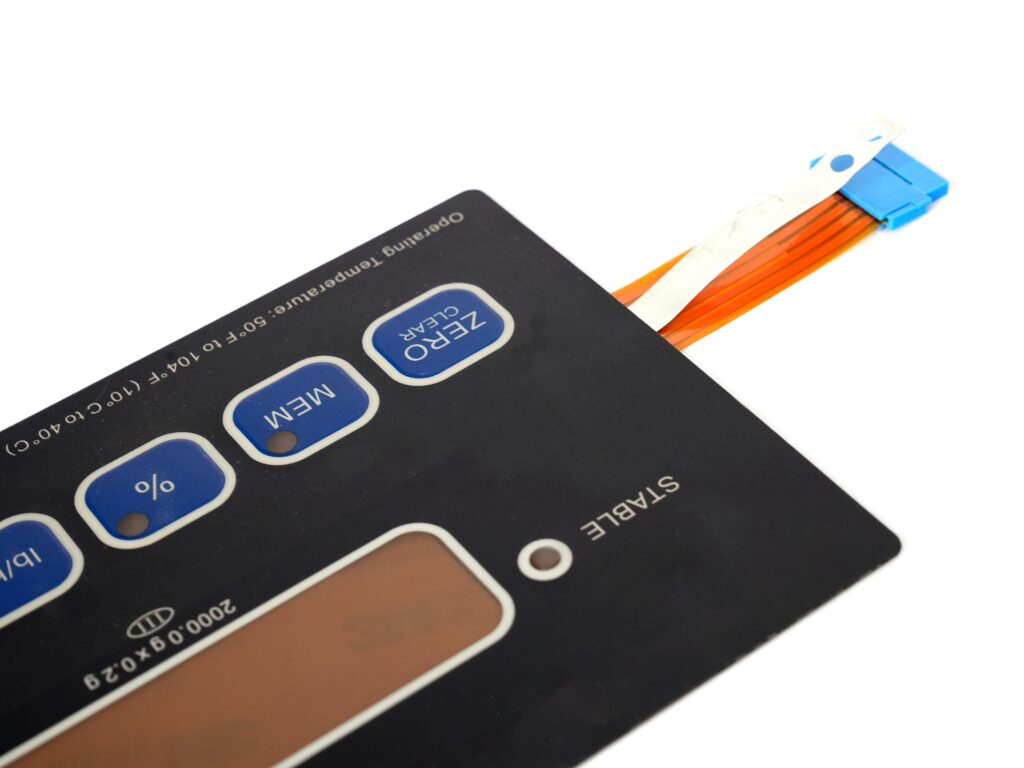

Membrane switch is an operating system that integrates key functions, indicator components, and instrument panels. It consists of four parts: panel, upper circuit, isolation layer, and lower circuit.

When the membrane switch is pressed, the contact of the upper circuit deforms downward and contacts the plate of the lower circuit. After the finger is released, the contact of the upper circuit rebounds, the circuit is disconnected, and the loop triggers a signal. The membrane switch has a rigorous structure, beautiful appearance, good sealing, moisture resistance, and long service life.

What is a membrane button?

A membrane button is a form of user interface control that works through a thin and flexible surface, usually made of plastic or polyester layer. Its working principle is to apply pressure to a specific point on the membrane to activate the circuit below.

Unlike typical mechanical buttons, membrane buttons have no moving parts, making them very rugged, wear-resistant, and ideal for clean environments and harsh conditions.

They can often be part of a larger membrane switch assembly and can be designed to have a tactile feel to let the user know that the button press has been registered. Its applications include medical devices, consumer electronics, and industrial equipment that require low-profile, cost-effective, and reliable input solutions.

How is a membrane switch made?

Membrane switches are products made by bonding several layers of films of different materials. The thickness is usually between 1.2mm and 2.5mm. It has the dual functions of panel and switch, so it is also called panel switch or thin plate switch.

This type of switch has a short action stroke of only about 0.25mm to 0.5mm, and the switch pressing force is 0.5N to 1N. It is very sensitive and can complete the switch action with a light touch, so it is also called touch switch or touch keyboard.

The production process of membrane switches mainly includes the following steps:

- Design graphics: First, design the required graphics and circuits on the film substrate.

- Layer bonding: Layers of films of different materials are laminated and bonded together to form a multi-layer structure. Common layers include panel, surface glue, upper circuit, isolation layer, lower circuit and bottom glue.

- Circuit production: Conductive materials are printed on the upper and lower circuit layers to form the electrical connection part of the switch.

- Assembly and testing: Finally, the various parts are assembled and functional tests are performed to ensure the normal operation of the switch.

What are the characteristics of a custom membrane switch?

- Personalized design: Custom membrane switches can be personalized according to the specific needs of customers. Designers can give full play to their creativity and integrate membrane switches with the overall design style of the product to enhance the aesthetics and brand image of the product.

- Multifunctional integration: Custom membrane switches can integrate multiple functions, such as buttons, indicator lights, display screens, etc. Through reasonable design, these functions can be integrated on a membrane switch, reducing the space occupation of the product and improving the integration of the product.

- High-quality materials: Custom membrane switches are usually made of high-quality materials, such as PET, PC, ITO, etc. These materials have good insulation, conductivity and mechanical properties. At the same time, custom membrane switches can also use special materials to meet the use requirements in different environments.

Strict quality control: The production process of custom membrane switches usually needs to undergo strict quality control, including raw material inspection, production process monitoring and finished product inspection.

What are the advantages of a custom membrane switch?

The core advantages of custom membrane switches are their high degree of customization, durability, sealing and cost-effectiveness.

Custom membrane switches can be designed according to specific needs to meet specific functional and usage environment requirements, while having long life, waterproof and dustproof characteristics, and high cost-effectiveness.

First of all, the high degree of customization of custom membrane switches is one of its biggest advantages. Through silk screen technology and design, any desired pattern and function can be produced to meet the needs of different application scenarios.

Secondly, custom membrane switches have excellent durability and long life. Due to its reverse printing technology and high-quality materials, the service life of membrane switches can generally reach more than five million times, or even higher.

In addition, custom membrane switches also have excellent sealing. Through unique technology, membrane switches can effectively prevent the intrusion of water, oil and other harmful substances, ensuring that the equipment can work properly in various environments.

Finally, the cost-effectiveness of custom membrane switches is also very significant. Due to the optimization of its materials and manufacturing process, the cost of membrane switches is relatively low, especially the price of some products is only a few cents, which is very economical for large-scale production and application. At the same time, the easy installation of membrane switches further reduces the cost of use.

What are the application areas of a custom membrane switch?

- Electronic equipment: Custom membrane switches are widely used in the field of electronic equipment, such as mobile phones, tablets, digital cameras, game consoles, etc. It can be used as the operation panel of the equipment, providing functions such as buttons, indicators and displays.

- Household appliances: Custom membrane switches are also widely used in the field of household appliances, such as microwave ovens, induction cookers, washing machines, refrigerators, etc. It can be used as the control panel of household appliances, providing functions such as operation buttons, indicators and displays.

- Medical equipment: Custom membrane switches also have important applications in the field of medical equipment, such as blood glucose meters, blood pressure meters, electrocardiographs, etc. It can be used as the operation panel of medical equipment, providing functions such as buttons, indicators and displays, and can also meet the requirements of medical equipment for waterproofing, dustproofing and corrosion resistance.

Industrial control Custom membrane switches also have certain applications in the field of industrial control, such as instrumentation, automation equipment, CNC machine tools, etc. It can be used as an operating panel for industrial control equipment, providing functions such as buttons, indicator lights and display screens, while also meeting the requirements of industrial control equipment for waterproofing, dustproofing, corrosion resistance and anti-interference.

Why choose our custom membrane switch?

BEST Technology was established specifically to serve the membrane switch and related mechanical switch industries. As a professional metal dome and metal dome array manufacturer in China, we have many years of experience in this field and guarantee to provide high-quality products, competitive prices, timely delivery and excellent after-sales service. We serve customers in domestic and international markets.

Our production equipment uses the most advanced technology, coupled with our highly qualified managers and researchers, to ensure the reliability and long-term stability of our products.

We have also formulated a very good warranty policy to guarantee that the metal dome and metal dome array will not have any potential defects. We strictly follow the operating procedures specified in ISO9001:2015 in terms of material procurement, product manufacturing, testing, packaging, marketing, etc.

Our products (metal domes, metal dome arrays) are used in a variety of applications, including but not limited to: industrial control interfaces such as membrane switches, buttons and nameplates, keyboards; electronic communications such as two-way radios (walkie-talkies), pagers, mobile phones, cordless phones, remote controls; payment devices such as POS machines, ATMs; automotive industry; medical equipment, ESU pencils; consumer products such as digital cameras, electronic dictionaries, MP3/MP4, smart home products, data acquisition equipment, etc.

Conclusion:

Customized membrane switches, as an excellent choice for personalized electronic interfaces, have the characteristics of personalized design, multi-functional integration, high-quality materials and strict quality control. With the continuous advancement and innovation of technology, customized membrane switches will develop in the direction of intelligence, flexibility and environmental protection, bringing more convenience and innovation to our lives and work.