As a unique electronic component, the membrane switch integrates the functions of buttons, indicator elements and decorative panels. It is usually composed of a membrane panel, conductive ink, an isolation layer, an adhesive and a backing adhesive. With its thin, soft, waterproof, dustproof and corrosion-resistant characteristics, it has shown excellent performance and broad application prospects in many fields.

What does a membrane switch look like?

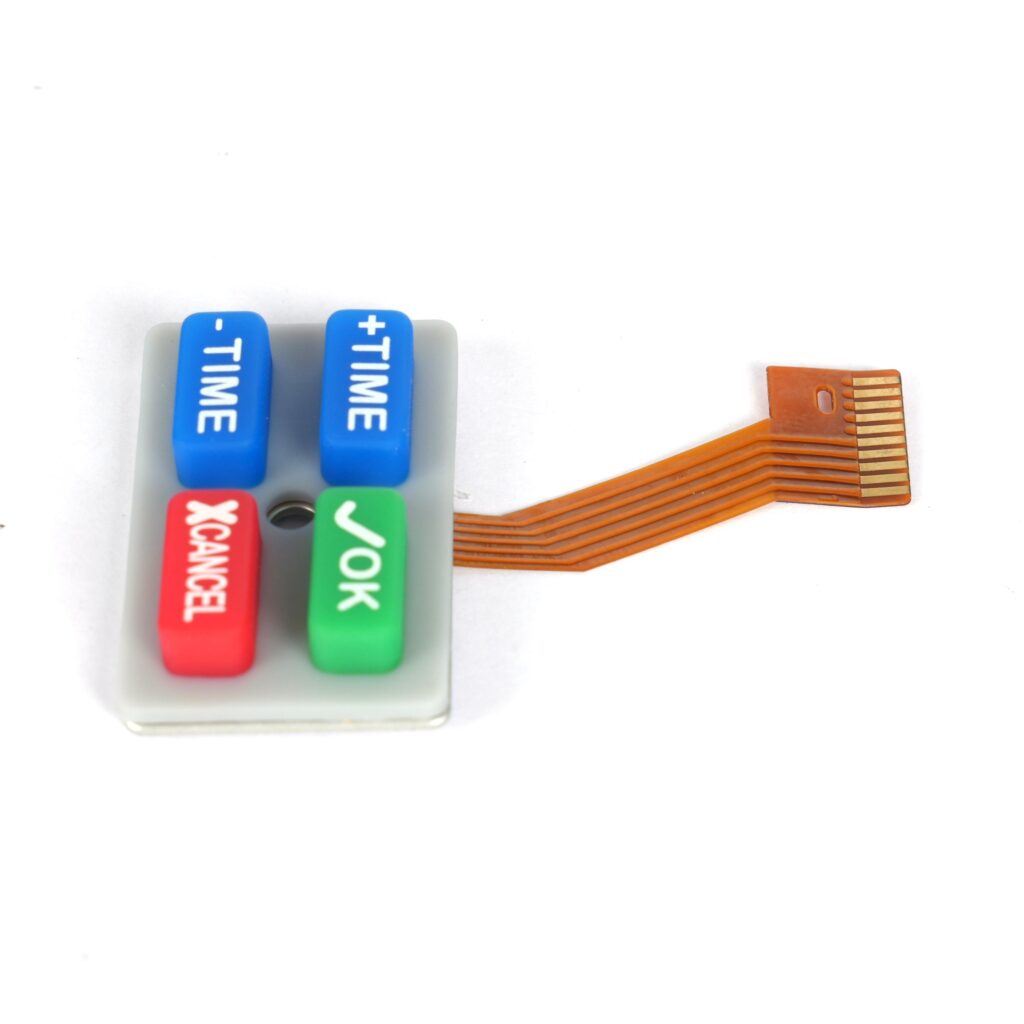

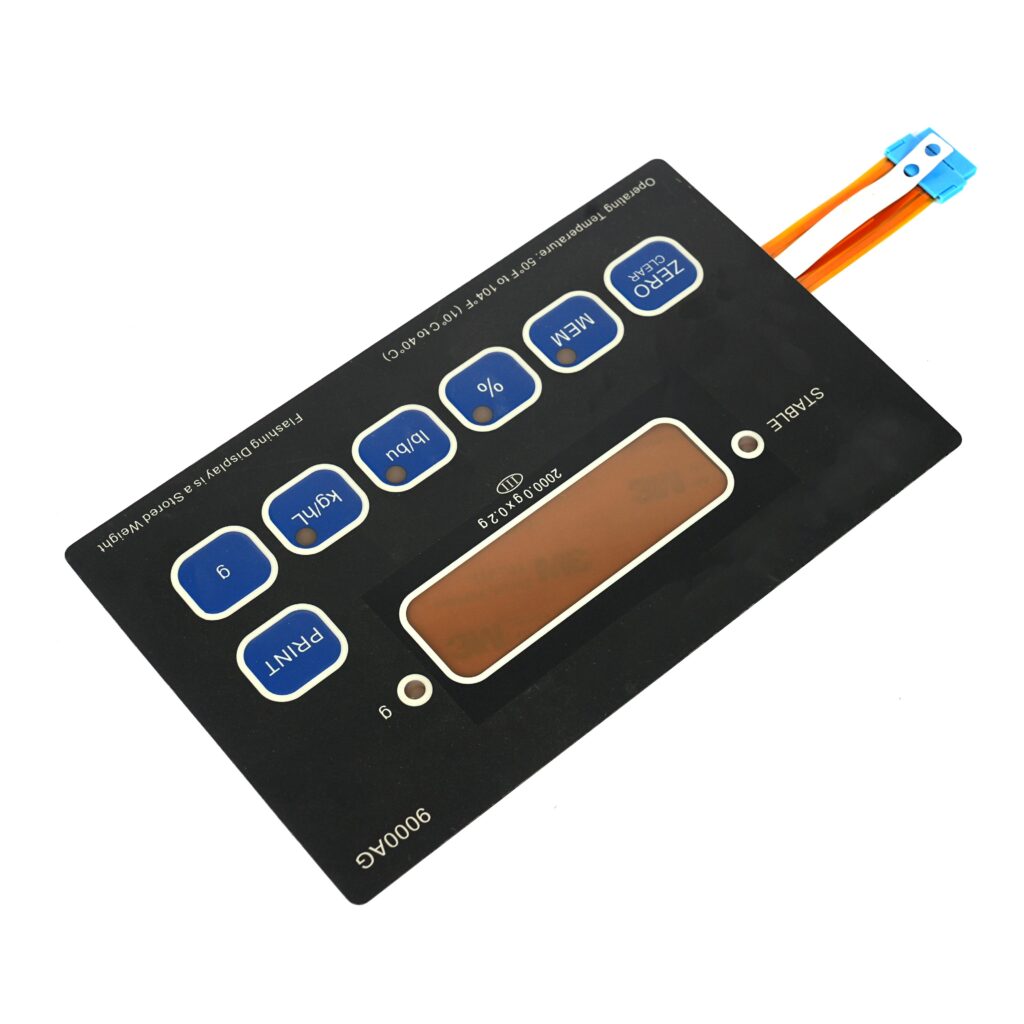

A membrane switch is an operating system that integrates button functions, indicator elements and instrument panels. It consists of four parts: a panel, an upper circuit, an isolation layer and a lower circuit. When the membrane switch is pressed, the contact of the upper circuit deforms downward and contacts the plate of the lower circuit. After the finger is released, the contact of the upper circuit rebounds, the circuit is disconnected, and the loop triggers a signal.

What is the function of a membrane switch?

When the membrane switch is pressed, the contact of the upper circuit deforms downward and contacts the plate of the lower circuit, thereby triggering a signal. When the finger is released, the contact of the upper circuit rebounds, the circuit is disconnected, and a signal input is completed.

The membrane switch realizes multiple functions through its unique structure and working principle. It can not only be used as an exterior decoration, but also as a simple switch button.

Based on the working principle of the membrane pressure sensor, the membrane switch is not picky about the base material and can realize many different functions. It can be integrated into the whole machine panel and used as a function mark to transmit the operation instructions to the rear circuit of the whole machine, thereby controlling the working state of the whole machine.

How long do membrane switches last?

The service life of the membrane switch can generally reach more than 1 million times. Since the action of the membrane switch is mainly realized by the vertical bounce of the elastic film, after millions of creeping, the creeping amplitude is very small, only 0.1-0.3mm, and the rationality of the material selection, the membrane material can withstand more than one million times of use without deformation.

The durability of the membrane switch is good, and its long service life lies in its design and material selection. The surface of the base material of the membrane switch is required to be flat and rust-free, and it can be installed after being cleaned with alcohol or gasoline.

Although the elastic film has undergone millions of creeping, the creep amplitude is very small, and the material selection is reasonable, so the membrane material can withstand more than one million times of use without deformation.

In addition, membrane switches also have the advantages of small size and light weight. Their total thickness is generally between 1.0 and 1.5 mm, which is only equivalent to the thickness of an ordinary aluminum panel. These characteristics make membrane switches widely used in various devices.

What are the different types of membrane switches?

There are many types of membrane switches, mainly including touch membrane switches, pressure membrane switches and capacitive membrane switches.

1. The touch membrane switch uses the change of mutual capacitance when the human body touches the switch area to realize the switch operation. It has a good operating feel, a simple structure, and stable operation.

2. The pressure membrane switch uses the principle of mechanical elasticity to realize the switch operation by contacting the switch contacts under pressure. It has high reliability and simple structure.

3. The capacitive membrane switch uses the electrostatic effect of the finger to detect the switch state. It has a fast response speed, no mechanical movement, and a long life.

In addition, membrane switches can also be divided into single-layer membrane switches, double-layer membrane switches and multi-layer membrane switches according to the structural form.

1. The single-layer membrane switch has a simple structure, low price, small size, and is suitable for occasions with simple circuit design.

2. Double-layer membrane switches have high performance, reliability and anti-interference ability.

3. Multi-layer membrane switches use multiple contact structures to achieve switch functions through crimping or lamination, and are suitable for occasions that require complex circuit design.

According to different sizes, membrane switches can also be divided into large membrane switches, medium membrane switches and small membrane switches. Large membrane switches are suitable for occasions that require a large number of switches, medium membrane switches are suitable for medium-sized circuit control, and small membrane switches are suitable for circuit embedded design and smaller occasions.

Are membrane switches tactile or linear?

Membrane switches are tactile switches. When the membrane switch is pressed, the contacts of the upper circuit deform downward and contact the plates of the lower circuit. After the finger is released, the contacts of the upper circuit rebound, the circuit is disconnected, and the circuit triggers a signal. This design of realizing the switch function through tactile feedback makes the membrane switch a tactile switch.

The working principle of the membrane switch is based on its unique structural design. It consists of a panel, an upper circuit, an isolation layer, a lower circuit and other parts. When the panel is not pressed, the upper and lower contacts are disconnected, and the isolation layer plays an isolation role. When the panel is pressed, the contact of the upper circuit deforms and contacts the lower circuit to conduct, thus triggering the signal. When the finger is released, the contact bounces back and the circuit is disconnected.

Membrane switches have many advantages, including rigorous structure, beautiful appearance, good sealing, long service life, and strong durability. Due to its simple structure, easy installation, and good feel, membrane switches are widely used in home appliances, medical equipment and other fields, gradually replacing some of the touch switches in the market.

What are 4 different types of rapid prototyping?

There are mainly 4 different types of rapid prototyping of membrane switches: flat touch type, hot pressing convex feel type, metal shrapnel type, and capacitive induction type. However, due to the lack of operating feel, it is easy to cause repeated operation or misoperation.

Flat touch type: This type of membrane switch uses a thin film substrate to print the conductor, and does not use a secondary process. Its advantages are high key life, which can reach one million times, and a large contact area to ensure the conduction rate.

Hot-pressed convex feel type: This type uses a film material to print the contact surface and then roll up the convex points to form a rebound force. The advantages are high life, up to more than 500,000 times, good feel, and the stroke and force can be customized according to customer needs. The disadvantages are that the mold cost is high, and use in a high temperature environment may cause the key force to weaken.

Metal shrapnel type: This type uses metal shrapnel as a conducting medium, with good touch and stable conductive properties. The advantages include uniform force and a crisp sound during operation. The disadvantage is that it may cause a short circuit or malfunction when the lining is uneven.

Capacitive induction type: This type uses a conductor to sense conduction, similar to a capacitive touch screen, and can sense action within a certain distance. The advantage is that the sensing distance can be designed according to customer needs, but the disadvantage is that the finished product qualification rate is low and it is sensitive to surrounding electromagnetic interference.

What is the difference between a membrane switch and a mechanical switch?

The main differences between membrane switches and mechanical switches are their working principles, usage experience, sealing, and application scenarios.

The core difference between membrane switches and mechanical switches lies in their different working principles. Membrane switches trigger key signals by pressing to close the circuit, while mechanical switches trigger signals through the physical movement of mechanical parts.

In terms of user experience, membrane switches require less force to trigger and react faster, but the feel may not be as comfortable as mechanical switches; while mechanical switches require greater force to press and the reaction time may be slightly longer.

In terms of sealing, membrane switches have better sealing, can effectively prevent water and moisture from entering, and are suitable for use in places that require waterproofing.

Finally, in terms of application scenarios, membrane switches are widely used in electronic communications, medical equipment, automotive industry and other fields due to their good sealing and long service life; while mechanical switches are often used in devices that require clear touch due to their clear physical feedback and high durability.

What are the applications of membrane switch?

Membrane switch is a new type of electronic component that is widely used in many fields. It has the characteristics of moisture resistance and long service life, and can work stably in various environments.

The specific application areas of membrane switches include:

1. Instruments: such as measuring instruments, analytical instruments, navigation instruments, medical instruments, etc.

2. Electromechanical products: such as CNC machine tools, electronic scales, robots, printing machinery, etc.

3. Computers: such as operating keyboards, monitors, printers, plotters, etc.

4. Household appliances: such as remote controls, electronic locks, washing machines, microwave ovens, rice cookers, audio and video equipment, etc.

5. Office systems: such as telephones, fax machines, copiers, computers, etc.

6. Electronic toys: such as electronic pianos, game consoles, etc.

The characteristics of membrane switches include:

1. It has good waterproof, dustproof, oil-proof and anti-harmful gas erosion performance.

2. Stable and reliable performance, light weight, small size and long life.

3. Convenient assembly, the panel can be washed without damage to the characters.

4. Rich colors, beautiful and generous.

Conclusion:

In conclusion, rapid prototyping technology has brought many benefits to the development of membrane switches, greatly shortening the development cycle, reducing costs and improving product quality. With the continuous advancement and innovation of technology, membrane switches will continue to expand their application scope in the future.

BEST Technology was established specifically to serve the membrane switch and related mechanical switch industries. We have many years of experience in this field and guarantee to provide high-quality products, competitive prices, timely delivery and excellent after-sales service.