What are SMD Switches?

Surface Mount Device (SMD) switches are tiny electronic components designed for mounting directly onto the surface of PCBs. Unlike traditional through-hole switches, which require leads to be inserted into holes on the PCB, SMD switches sit on the board’s surface. This design allows for a more compact, lightweight, and cost-effective assembly process, especially useful in modern electronic devices where space is at a premium.

SMD switches come in various forms and are used in a wide range of applications, from consumer electronics to industrial equipment. They play a crucial role in user interfaces, providing the means to turn devices on or off, adjust settings, or input commands.

How do SMD Switches Work?

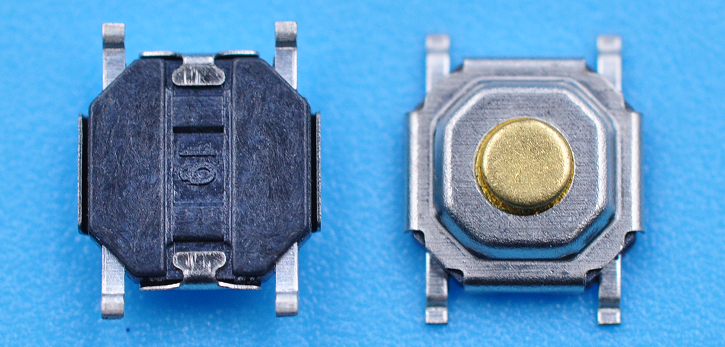

SMD switches operate by creating or breaking an electrical connection in a circuit. When the switch is pressed, it closes the circuit, allowing current to flow. Releasing the switch opens the circuit, stopping the current flow.

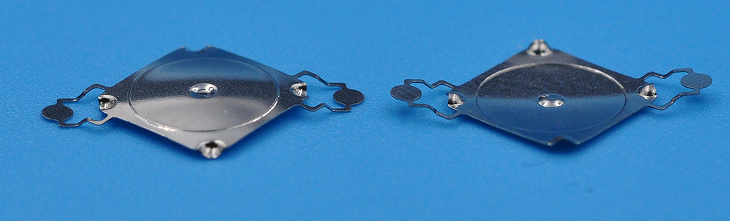

Inside an SMD switch, a small metal contact is pressed down onto a conductive pad on the PCB when the switch is activated. This contact bridges the gap between two conductive traces on the PCB, completing the circuit. The switch returns to its original position when released, thanks to a small spring or other mechanism inside the switch. The design of SMD switches ensures reliability and durability. Despite their small size, they can withstand thousands or even millions of actuations without failure.

Types of SMD Switches

SMD switches come in various types, each designed for specific applications and environments.

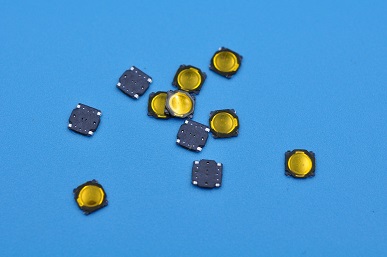

1. Tactile Switches

Tactile switches are among the most common types of SMD switches. They provide a physical and audible “click” when pressed, giving users feedback that the switch has been activated. This tactile response is valuable in applications where users need confirmation that a button has been pressed, such as in keyboards, calculators, and control panels. They are available in various sizes, actuation forces, and configurations to suit different applications.

2. Slide Switches

Slide switches allow users to make a selection between two or more positions by sliding a small lever. These switches are commonly used in applications where space is limited, such as in portable electronics and handheld devices. They are often used to control power, select modes, or switch between different functions.

3. Push Button Switches

Push button switches are straightforward in design, with a button that users press to activate the switch. They can be momentary (only active while pressed) or latching (stays active until pressed again). Push button switches are used in various applications, from power switches on devices to reset buttons on circuits.

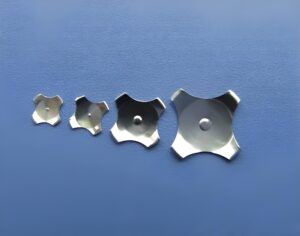

4. Rotary Switches

Rotary switches allow users to select between multiple options by rotating a knob or dial. They are commonly used in applications where users need to choose between several settings, such as in audio equipment, instruments, and control panels. Rotary switches are reliable and offer clear, positive detents for each position.

5. DIP Switches

DIP (Dual In-line Package) switches consist of a series of small switches mounted in a single package. Each switch can be individually toggled, allowing for various configurations or settings. DIP switches are often used for setting options or configurations on PCBs, such as addressing, mode selection, or enabling/disabling features.

Benefits of SMD Switches

The advantages of SMD switches go beyond their compact size and reliability. One key benefit is the cost savings in manufacturing, as these switches can be mounted onto PCBs using automated pick-and-place machines. This automation reduces labor costs and enhances production efficiency.

Moreover, SMD switches are easier to integrate into designs due to their small footprint. They also offer lower parasitic capacitance and inductance compared to through-hole switches, which is particularly beneficial for high-frequency circuits. Overall, SMD switches contribute to the creation of high-quality, compact electronic devices that are economical to produce.

How to Choosing the Right SMD Switch?

Selecting the right SMD switch for a project involves considering several factors, including the application, environment, and specific requirements of the device. Here are some key considerations to keep in mind:

1. Application Requirements

The first step in choosing an SMD switch is to understand the specific requirements of the application. This includes the type of actuation needed (momentary or latching), the desired tactile feedback, and the size constraints of the device.

For example, tactile switches are ideal for user interfaces where feedback is important, while slide switches may be better suited for mode selection in compact devices. Understanding the application’s needs will help narrow down the options and select the most suitable switch.

2. Environmental Considerations

The environment in which the SMD switch will be used is another crucial factor. For example, switches used in outdoor or harsh environments may need to be sealed against moisture, dust, or other contaminants. In contrast, switches for consumer electronics may prioritize a sleek, low-profile design.

3. Electrical Specifications

The electrical specifications of the SMD switch, such as voltage rating, current rating, and contact resistance, must match the requirements of the circuit. Additionally, consider the switch’s bounce time, which can affect the performance of high-speed or sensitive circuits. A switch with low bounce time is preferable for applications where precise timing is critical.

4. Mechanical Durability

The mechanical durability of the SMD switch, including its actuation force, travel distance, and lifespan, should match the needs of the application. For example, a switch used in a frequently operated control panel should have a high actuation life and a comfortable actuation force to prevent user fatigue.

5. Cost and Availability

Finally, consider the cost and availability of the SMD switch. While it may be tempting to choose the most advanced or feature-rich switch, it’s essential to balance performance with cost, especially in high-volume production.

FAQs about SMD switch

1. How do I mount an SMD switch on a PCB?

SMD switches are typically mounted on PCBs using automated pick-and-place machines. The switches are placed onto solder paste on the PCB surface and then passed through a reflow oven, where the solder melts and bonds the switch to the board.

2. How long do SMD switches last?

The lifespan of an SMD switch depends on its design and the specific application. High-quality SMD switches can last for millions of actuations. Factors such as the switch’s construction, the materials used, and the operating environment will influence its durability.

3. Can SMD switches handle high current?

SMD switches are typically designed for low-current applications, as their compact size limits the amount of current they can safely handle. However, there are specialized SMD switches with higher current ratings for specific applications. It’s important to check the switch’s electrical specifications to ensure it meets your circuit’s current requirements.

4. How do I test SMD switches during assembly?

SMD switches can be tested during assembly using automated testing equipment such as bed-of-nails testers or flying probe testers. These systems can check the electrical continuity of the switch and verify its operation by simulating user inputs.

5. What are common issues with SMD switches and how can they be prevented?

Common issues with SMD switches include poor solder joints, contamination, and mechanical damage. These can be prevented by ensuring proper PCB design, using high-quality materials, and following best practices during assembly, such as controlling humidity and temperature and avoiding excessive mechanical stress.

6. What are the alternatives to SMD switches?

Alternatives to SMD switches include through-hole switches, which are mounted by inserting leads into PCB holes, and capacitive touch switches, which use a touch-sensitive surface instead of a mechanical actuator. The choice between SMD and alternatives depends on the specific requirements of the application.