At Best Technology, we offer metal dome & metal dome arrays to provide tactile feedback with our membrane switches. Custom dome arrays as a standalone part that can be applied to circuit boards as well. We provide metal dome assembly service to let you enjoy the one-stop service.

What Are Dome Arrays?

Dome arrays called metal dome array or dome sheet. They are essential components in various electronic devices, particularly in interfaces where precise tactile feedback is crucial. They consist of a collection of metal domes arranged on a flexible substrate, often made of materials like polyimide or polyester. These polyester films are always lined with adhesive. The adhesive backing can be removed and applied directly onto a circuit board (often a printed circuit board, or PCB). These arrays are typically used beneath keypads or switches, providing a tactile “snap” when pressed.

The design of dome arrays can vary depending on the application, but they generally consist of multiple metal domes that function as individual switches. Each dome in the array acts as a contact point, bridging the circuit when pressed. This simple yet effective design is widely appreciated in industries where reliability and durability are key, such as in medical devices, automotive controls, and industrial equipment.

How Do Metal Dome Arrays Work?

The working mechanism of metal dome arrays is relatively straightforward but highly effective. Each dome in the array is slightly convex and rests above a circuit. When a user presses on the dome, it deforms and comes into contact with the circuit below, completing the electrical connection. This action generates a signal, indicating that the switch has been activated.

The snap action, or the tactile feedback, is one of the most significant features of metal dome arrays. This feedback is not just satisfying to the user but also serves as a functional assurance that the input has been registered. The force required to deform the dome and the resulting tactile feedback can be customized according to the specific needs of the application.

Types of Dome Arrays

Dome arrays come in various configurations, each tailored to meet specific application requirements. In Best Technology, when you ask for a metal dome arrays, the sales may question that which kind of dome arrays you want? Below are the different types of dome arrays offered by Best Technology, along with their unique structures and uses. Hope it makes sense.

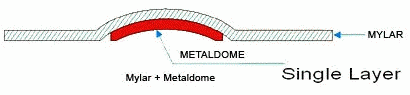

Single Layer Dome Arrays

Single layer dome arrays are the most basic type, consisting of a single layer of metal domes lined up on the polyimide/PET. These arrays are straightforward in design and are often used in applications where simplicity and cost-effectiveness are key. This type of metal dome array is used in the early period of dome arrays industry. Metal dome contacts are attached under Mylar (one layer of adhesive PET film). On the sheet, there is an air hole for each dome contact and it is essential for good click-feeling. Here you can see its structure:

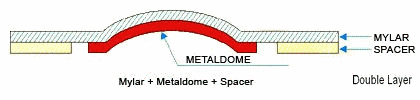

Double Layer Dome Arrays

Double layer dome arrays add an additional layer to the structure, and attached under the metal dome contacts. The extra layer often serves as a spacer or insulator, which used for improving the tactile response and protecting the underlying circuitry. In addition, air paths between dome arrays helps reduce the chance for PET film being damaged by metal dome contacts’ burr and block dust coming into PET films. This design is particularly beneficial in automotive controls or industrial equipment, where the devices are subjected to harsh conditions and frequent use. Below is its structure and you can see the spacer is under the mylar layer.

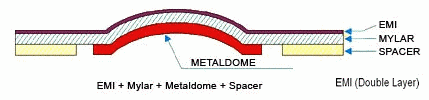

EMI Printing Dome Arrays

EMI (Electromagnetic Interference) printing dome arrays are designed to minimize interference in electronic devices. They are similar to the normal metal dome arrays, but with the EMI shielding. These arrays are printed with an EMI shield, which helps in blocking unwanted electromagnetic signals that can disrupt the performance of the device. Electrostatic is gathered on the printed silver paste or silver carbon paste and neutralized. This type of dome array is essential in applications where signal integrity is critical, such as in telecommunications equipment, medical devices, and other high-precision electronic devices.

EMI printing dome arrays can be divided into EMI single layer and EMI double layer. No matter which kind of EMI metal array, the electrostatic is print on the top layer of metal dome arrays. You can see their structure in detail.

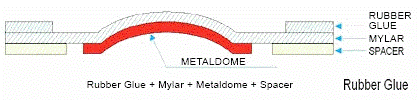

Rubber Glue Dome Arrays

Rubber glue dome arrays incorporate a layer of rubber adhesive that holds the domes in place. This design is particularly useful in applications where the dome array needs to be flexible and conform to curved or irregular surfaces. Because material of adhesive is Silicone, so it also named Silicon or Acrylic PSA adhesive tape.

LGF Dome Arrays

The full name of LGF dome array is light guide film dome arrays. It is a new design metal dome array, add a LGF layer on the top of normal dome array. These arrays incorporate a light guide film that distributes light evenly across the surface, making the keys easier to see and use. As everyone knows, the light under keypad is coming from the LED on PCB motherboard. We need to put about 8-10 pieces LED on each board, but if the design changed to use LGF, then we can save several LED, as well as SMT fee.

This type of dome array is commonly used in devices that require backlit keypads, such as smartphones, gaming controllers, and automotive controls. The integration of LGF not only improves usability but also adds a sleek and modern appearance to the device.

Custom Dome Arrays

Custom dome arrays are specifically designed to meet the unique needs of a particular application. These arrays can vary in size, shape, actuation force, and material, depending on the requirements of the device. Customization allows for the creation of dome arrays that are perfectly suited to the intended use, ensuring optimal performance and user experience. Whether it’s for a specialized medical device, an industrial control system, or a unique consumer product, custom dome arrays provide the flexibility to design a solution that meets exact specifications.

Best Technology Metal Dome Arrays Capability

| Total Height | 0.28-0.45 mm |

| Travel | 0.13-0.30 mm |

| Scope of Force | 100-400 gf |

| Tolerance of Force | ±25 gf |

| Click Ratio | >30% |

| Life Cycles | >1 Million Cycles |

| Salt and Fog Examination | 35±2°C, 5±0.1%, 48H |

| Working Temperature | -20°C-50°C |

| Working Humidity | Under 100%RH |

| Touch Resistance | <1 ohm |

| ESD Resistance | <3 ohm |

| Dimension Tolerance | ±0.05-±0.15mm |

Since 2006, we have worked in manufacturing metal dome and dome arrays, though several types of dome arrays are developed in recent year, we have rich experience and mature manufacturing skills in this industry. And there is no doubt that we are one of the leaders of metal dome and dome arrays in Asia or even all the world. We offer custom-built metal domes to fit the exact specifications of your product—our manufacturing facility can custom-cut almost any shape and size.

How Do Dome Structures Work?

Dome structures in general, including those used in dome arrays, work on the principle of load distribution. The dome shape naturally distributes force evenly across its surface, which is why it is commonly seen in architecture and engineering. This same principle is applied in dome arrays, where the dome’s shape ensures that the force exerted by the user is evenly distributed, leading to consistent and reliable performance.

When you press down on a dome, the structure deforms in a controlled manner, allowing for a predictable and repeatable actuation force. The even distribution of force also contributes to the longevity of the dome array, as it minimizes wear and tear on the individual components.

Benefits of Metal Dome Arrays in Membrane Switch

In general, there are five advantages to using metal dome arrays in membrane switches:

- Tactile feedback

- Durable (1 million + actuations)

- Thin and light

- Highly customizable

- Low cost and good for mass production

Metal Dome Array Use Cases

Metal dome arrays are used in various industries and applications, including:

- Consumer electronics

- Industrial equipment

- Electronic

- Automotive

- Military

- Medical

- Agriculture

- Transportation

- Aerospace

- Telecommunications

With our extensive customization options, you can transform any membrane switch into a robust user interface with tactile feedback. Create a product that considers every aspect of user interaction—contact Best Technology for tactile dome array!