Regarding the installation and welding of metal domes

The installation of metal domes has always been one of the issues that customers are more concerned about. Many customers will ask about the installation of the triangular metal dome before purchasing a dome, so let me tell you about the installation of the dome and what are its effects?

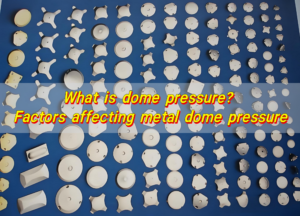

What are the specifications of triangular metal domes?

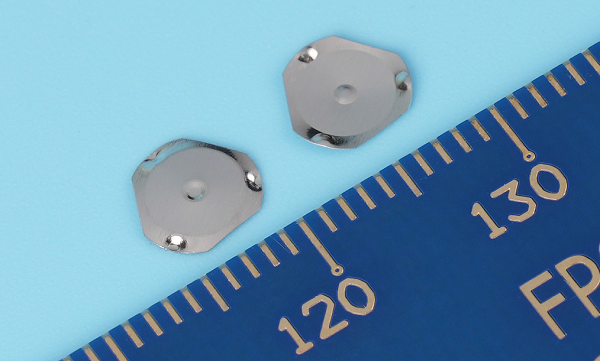

First we have to consider the specifications of the metal dome. Triangular metal domes are specifically divided into two types: with legs and without legs. Triangular domes with legs are also distinguished according to the length of the legs, usually 3.0MM, 1.6MM, and 0.8MM. The width of the feet is usually 0.8MM, but there are also some customized models that require a suitable installation method to be designed according to the specific length.

Triangular Metal Dome Life Strength

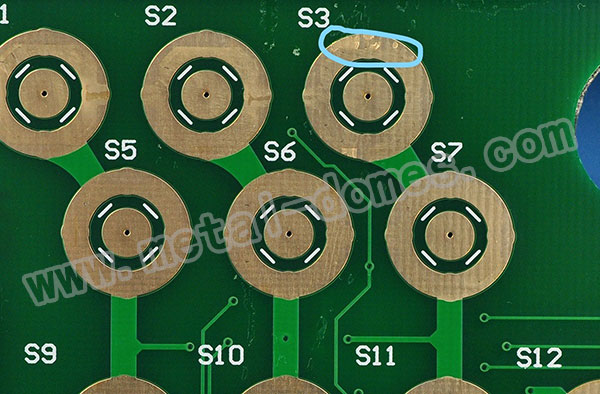

The principle of using the triangular metal dome is that it can function as a conductive circuit on the PCB board. When the dome is pressed down, the four sides of the dome will extend to a certain extent. If the two legs of the dome are welded and fixed, when the dome is pressed down, the dome will not extend to the surroundings, but the force will increase, and the service life of the dome will be shortened, making the dome unable to Use its special properties normally. In normal use, the life of the metal dome can reach 5 million times. When the metal dome is used in products, it will be affected by the environment, but the service life can also be maintained at millions of uses.

How to install dome more stably?

If the triangular dome is installed unstablely, the metal dome can easily fall off or become dislocated during use, which will affect the operation and functionality of the product. Then you can choose to use a metal dome array. Simply put, a layer of film is added on top of the metal dome to fix the position of the metal dome. When the dome is pressed down, it will not affect its extension to the surroundings and will not affect the working principle of the dome. And the installation is simpler than metal dome and more stable in use.

What is the difference between metal domes with dots and without dots?

Metal domes without dots, such as round domes, oval domes and other metal domes without dots, are mostly used in micro switches, mobile phone buttons, remote controls and other products. There are also cross-shaped domes, which are mostly used in Among products such as membrane switches and PCB boards, the metal dome array of these products has relatively high conductivity requirements. These products have relatively high requirements for the production environment and need to be produced in a dust-free workshop. If there is dust contamination during production, , will affect the conductivity of the metal dome.

The dotted metal dome is a metal dome with a protruding point in the middle. After product use testing, the dotted metal dome can effectively reduce poor conduction performance. If dust enters during use, the dust will only appear around the bumps. At the same time, after pressing, the dust can fall off through vibration. This also prevents it from affecting the service life of the metal dome and reduces poor conductivity.

Pingback: Metal Dome (metaldomes) | Pearltrees