Metal dome is a common electronic mechanical component that is elastic and widely used in many fields. It plays an important role both in mechanical manufacturing and electronic equipment. Below we will delve into its key knowledge and applications. We will start from the structure, material, manufacturing process and application fields, so that everyone can better understand and apply this important metal component.

Structure and type

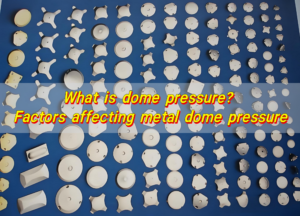

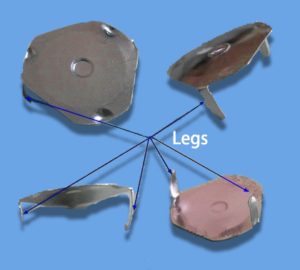

Metal domes have resilience and bending capabilities, usually in the shape of sheets or strips, and are used for various mechanical keys, switches, shock absorption and other functions. Metal domes can be divided into various types according to different shapes and uses, such as:

1. Rectangular dome: rectangular or square, often used to connect and fix components, and has good load-bearing capacity.

2. Circular dome: ring-shaped or circular, suitable for connection, fixing and damping scenarios.

3. Oval dome: curved shape, usually used to bear local loads or adjust assembly gaps.

Materials and properties

The material of the metal dome is usually made of highly elastic metal materials, such as stainless steel, carbon steel, alloy steel, etc. These materials have excellent elasticity, corrosion resistance, wear resistance and other properties, allowing the dome to maintain its functionality in various harsh environments.

Main features

1. Load bearing capacity: Domes of different sizes and materials have different load bearing capacities, and appropriate specifications can be selected according to needs.

2. Corrosion-resistant and wear-resistant: When suitable materials are selected, the dome can resist corrosion and wear and maintain a long service life.

3. Elastic recovery: The dome can quickly return to its original shape after being stressed, maintaining its elasticity and bending ability.

Manufacturing process

The manufacturing process for metal domes typically includes the following steps:

1. Material selection: Choose appropriate materials, usually metal materials, such as stainless steel or carbon steel.

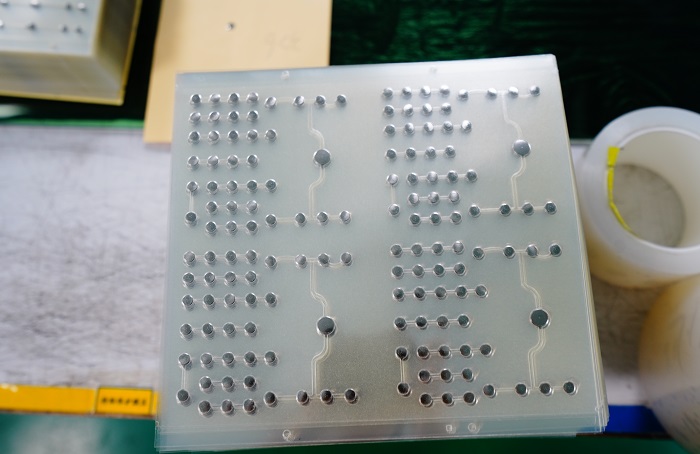

2. Stamping: Use equipment such as a punch machine to stamp the metal sheet to obtain the required dome shape.

3. Bending and bending: The stamped metal sheet is bent and bent to form the specific shape of the dome.

4. Heat treatment: In some cases, the dome needs to be heat treated to improve its elasticity and durability.

5. Surface treatment: Surface treatment of the dome, such as galvanizing, nickel plating, etc., to improve corrosion resistance.

How to buy the right metal dome?

1. Material selection: Select the appropriate material according to the application environment of the product to ensure that the metal dome has sufficient feel and corrosion resistance.

2. Specifications and sizes: Choose appropriate specifications and sizes according to actual needs, as well as the shape of the metal dome, to ensure that the dome can function normally in use.

3. Performance test: Before mass production, samples need to be tested for performance to ensure the quality of the dome.

Best Technology has rich design and production experience and a professional design team that can design metal domes according to customer needs. At the same time, it can conduct manufacturability analysis of the product through DFM to make the metal dome perfectly fit your product. Come in for a consultation!