Metal domes are made from ultra-thin and extra-thick (usually high-hardness) stainless steel. The metal dome is an important part of the switch. Metal domes are mainly used for membrane switches, contact switches, PCB boards, FPC boards, medical equipment and other products. Next, I will introduce to you in detail the production process of metal domes and the application fields of domes.

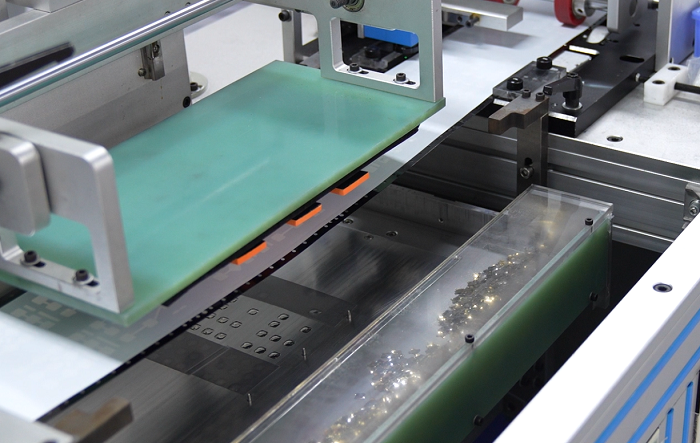

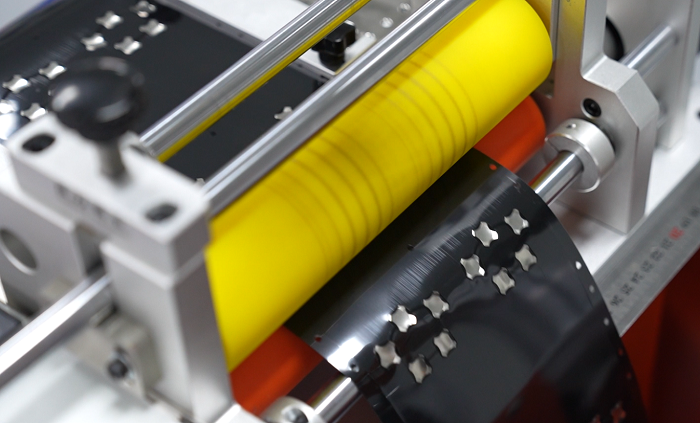

First of all, the production process of metal domes can be roughly divided into the steps of raw material preparation, material processing, molding processing, surface treatment and quality inspection. Among them, raw material preparation is the basis of the entire production process, which requires high quality and consistent specifications of raw materials. The selection of raw materials will also be adjusted according to customer requirements. Material processing mainly involves cutting, drilling, etc., with the purpose of processing raw materials into semi-finished products that meet the requirements; forming processing involves shaping semi-finished products through cold heading, stretching, etc.; surface treatment mainly involves nickel plating on the dome surface Processing makes the dome have better physical properties; quality inspection is a comprehensive inspection of the finished product to ensure that it meets quality standards.

Inspection steps during the production process are also crucial. From the incoming inspection of raw materials to the outgoing inspection of finished products, every process of Best Technology is strictly inspected to ensure that the domes are of excellent quality and meet the requirements. Among them, the most important inspections include appearance inspection, dimensional inspection, hardness inspection, tensile test, etc. Only through various inspections can the quality and performance of the dome be ensured to be optimal.

Metal domes are widely used in different industries, and their versatility and reliability make them an essential part of many industrial processes. When selecting a suitable metal dome, its characteristics and adaptability need to be considered to meet the needs of a specific industry.

Automotive Manufacturing

Metal domes play an important role in the automotive manufacturing industry. They are commonly used in braking systems to absorb shock and control vehicle movement. In addition, metal domes can also be used in the valve system of car engines to ensure their proper operation and improve fuel efficiency.

Electronic field

Metal domes are also widely used in the electronics industry. They are commonly used in connectors and switches in electronic equipment to provide stable electrical connections and reliable switching operation. In addition, metal domes can also be used in the cooling system of electronic equipment to maintain the normal operating temperature of the equipment.

Medical industry

Metal domes are of great significance in the medical industry. They are widely used in remote control devices in wards. The remote control device at the bedside of the ice rink uses metal domes to transmit instructions. There are also some medical machines used by doctors during surgeries, which also have metal domes built into them. The plasticity of metal domes makes them an integral part of these devices.

aerospace industry

The aerospace industry has even more demanding demands on metal domes. Metal domes are widely used in the high-temperature and high-pressure environments of aircraft engines to control airflow and temperature. In addition, metal domes can be used in structural parts of aircraft to enhance their strength and durability.

energy industry

In the energy industry, metal domes are widely used in power generation equipment and transmission lines. The electrical conductivity and corrosion resistance of metal domes make them an important component in electrical equipment, used to protect circuits and transmit electrical energy.

So how do you choose the right metal dome? In addition to finding the right manufacturer, you must also know how to select the most suitable metal dome for product applications based on suitable dome conditions. Best Technology designs optimal solutions for customers based on their actual needs and product applications, allowing customers to experience the convenience and efficiency brought by Best Technology.