Customers often ask some questions when making early purchases. After summarizing these problems, today I will introduce to you the common problems of metal domes and what should be paid attention to during the installation of metal domes.

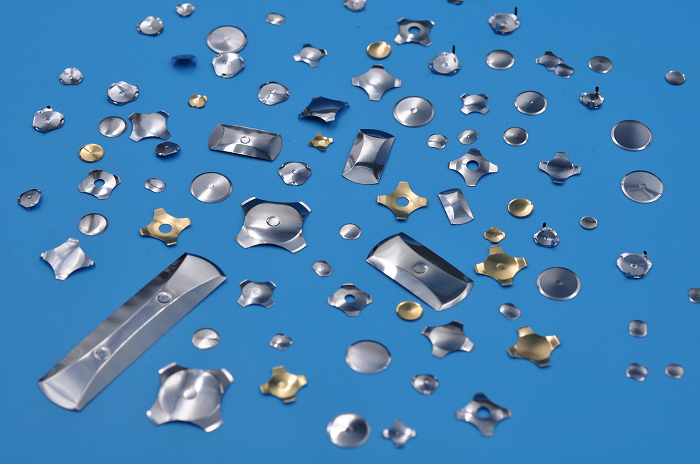

The first is the color of the metal dome: the metal dome is mainly made of stainless steel, with a silver surface. Some customers will need to surface treat the metal dome. The surface of the nickel-plated metal dome is golden yellow. This nickel-plated metal dome can better prevent surface corrosion during use and is more durable. Nickel-plated metal domes feel better in hand and work better than ordinary metal domes.

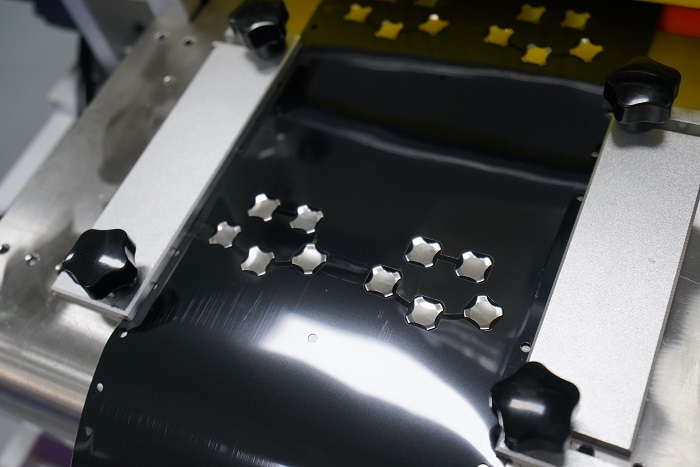

In addition to the metal dome, the color of the PET glue in the metal dome array has also become a focus of some customers. The PET glues we often use include white, transparent and black, among which white and transparent PET are widely used. However, the actual application still needs to be selected based on the needs of the customer and understand the metal dome array PET.

There will also be some customers who will ask some professional questions, and I will explain them here. Why does the Dome array PET tape lift up during use? In fact, PET is glued to the PCB, and the metal dome array should be flat under normal circumstances. After being used for a period of time, the outline of the dome array may tilt, causing dust to enter the PET, causing undesirable phenomena. So what is the reason for this?

When the dome array has a double-layer structure, the thickness of the upper polyester film is about 0.05mm, and the thickness of the lower spacer layer is about 0.075mm.

If the metal dome is a high-height series, such as a triangular metal dome or a metal dome with legs (height: 0.4-0.7mm), due to the height of the metal dome, the space between the metal dome and the gasket will be too large. Therefore, when the metal dome is close to the outline during use, the dome array in this area will tilt upward. We provide customers with two solution suggestions: The first is to keep the distance between the dome and the contour from being too close based on the actual application, leaving enough space to prevent tilting during use. Alternatively, you can make the shim thicker and add more adhesive to prevent the dome from tilting upward.

What are the benefits of making the dome into a dome array? The metal dome is a small dome in production. A layer of PET tape needs to be attached to the production dome array. First of all, it can prevent dust and contamination from entering, and it can also make the dome more firmly attached to the circuit board.

We will answer a series of problems encountered by metal domes one by one. Best Technology metal domes have strict requirements and control the Force of the metal domes evenly in all metal domes. After production, the dome will go through a series of tests to see if the product is qualified. The metal dome array is easy to save and install. The metal dome is positioned in PET and can be directly installed on the corresponding PCB board. Therefore, metal dome arrays are very popular with some customers, so mass production is common when producing metal domes and dome arrays. More relevant knowledge about metal dome will be continuously updated.