In the process of using metal dome adhesive patches, it is important to ensure that they remain flat. However, there are instances where an issue arises: when initially applied to the PCB board, the adhesive patch is flat, but after a period of time, the edges of the patch begin to lift, which can result in dust ingress and poor contact. So, what are the reasons for this problem?

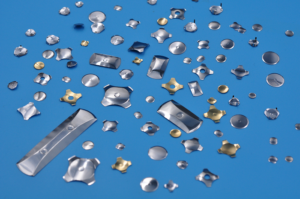

Metal domes have long been favored in electronic products. On the market, some subpar products, although inexpensive, reveal issues such as poor adhesion of the domes. Displacement or detachment frequently occurs after a period of use. These are the outcomes of inadequate inspection during production, resulting in flawed products. Hence, when purchasing membrane switches, it is essential to meticulously select suppliers. Below, we will introduce how to prevent the phenomenon of metal dome lifting.

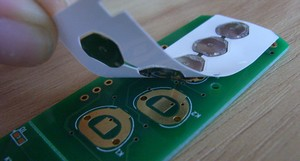

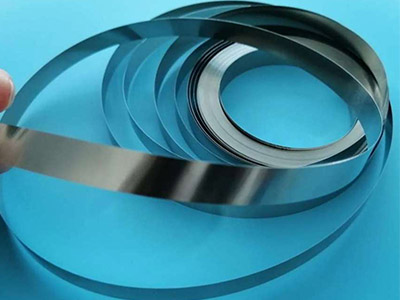

Dome adhesive patches possess a dual-layer structure. The upper layer typically has a thickness of 0.05mm, while the lower spacer layer has a thickness of about 0.075mm. The dome is situated within the lower spacer layer. If domes with relatively greater heights, such as triangular or cross-shaped domes (with a height of 0.4-0.7mm), are chosen, there can be a substantial height difference between the dome and the spacer layer. When the dome is positioned close to the edge, it can result in the dome adhesive patch lifting. To address this issue, there are two approaches. First, during design, ensure that the dome is not placed too close to the edge, allowing ample space to prevent lifting. Second, the spacer layer can be reinforced and enhanced with additional adhesive to prevent the dome adhesive patch from lifting.

Currently, membrane switches are in high demand as a switch category. Whether for industrial machinery or electronic digital products, the need for membrane switches is on the rise, and metal domes play a pivotal role in this field. Presently, small and lightweight devices, such as audiovisual products, digital products, remote controls, communication products, household appliances, security products, automatic spray guns, toys, computer products, fitness equipment, medical devices, counterfeit detection pens, laser pointer buttons, and more, widely utilize membrane switches. Many businesses, when making bulk purchases, often inquire about the lifespan of membrane switches. Through our measurements, we can confidently state that the lifespan is 5 million cycles. Compared to other manufacturers, when designing and producing metal domes, we adhere to customer-provided drawings and practical applications to ensure that our metal domes do not lift during use. We also provide customers with instructions on the correct installation of metal domes to prevent frequent pressing that could lead to the loss of elasticity in the dome.

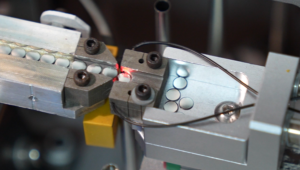

Best Technology has been specializing in metal dome production for over a decade. With a wealth of production experience in designing and producing metal domes and installing membrane switches, we can assure customers of product quality and fair pricing, enabling customers to use our products with confidence and peace of mind.