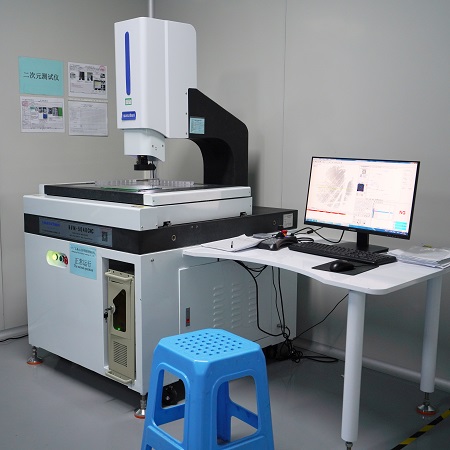

With development, not only has production efficiency improved, but there’s also continuous progress in quality inspection, leading to enhanced control over product quality. In the realm of precision engineering and manufacturing, even the minutest details can yield substantial changes. The role of advanced measurement instruments cannot be underestimated. The two-dimensional measurement instrument is an outstanding tool that completely transforms the inspection methods for metal dome arrays and domes. This cutting-edge device, also known as an image measuring instrument or video measuring machine, has become an indispensable asset in the fields of quality control and precision measurement.

What is a Two-Dimensional Measurement Instrument?

The two-dimensional measurement instrument is a technological marvel, seamlessly integrating meticulous measurement capabilities with advanced imaging functions. Its primary purpose is the accurate measurement of dimensions for metal domes and their corresponding molds. The measurement parameters encompass a wide range of geometric attributes, including positional accuracy, concentricity, straightness, contour precision, roundness, and various size-related measurements tied to reference points.

Key Features and Functions:

Comprehensive Geometric Measurement: This instrument excels in evaluating a multitude of geometric characteristics on a two-dimensional plane. It can measure diameters, radii, lengths, angles, widths, heights, depths, point-to-point distances, and even complex features like distances from points to lines and circle center distances.

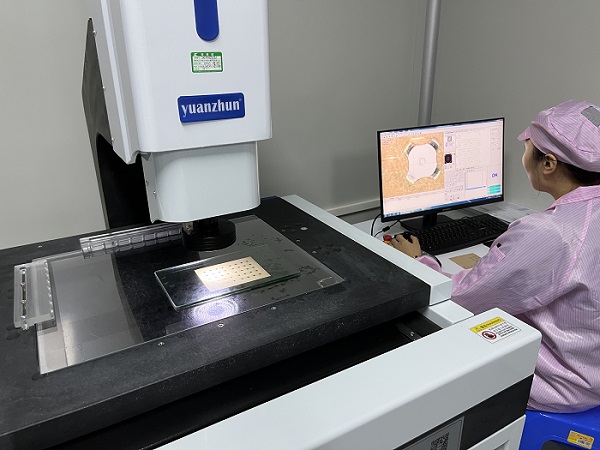

Visual Comparative Analysis: Through its built-in imaging capabilities, the instrument allows for intuitive and visual comparative analysis. By capturing images of parts and samples, operators can make precise and immediate visual comparisons, aiding swift decision-making.

Real-time Data Analysis: The accompanying software enables users to analyze measurement data in real time. This function enhances efficiency and enables timely adjustments and corrections during the manufacturing process in the event of deviations.

Seamless Data Export: Measurement data can be effortlessly exported to familiar formats such as Word and Excel, simplifying data analysis and integration into existing workflows.

Automated Edge Detection: The instrument’s automatic edge detection feature accelerates the measurement process, enhancing accuracy and efficiency in quality control operations.

Shortcut Functions: Operators can utilize shortcut key functions to expedite measurements, facilitating quicker and more convenient assessments.

Compatibility with AutoCAD: The instrument is designed to seamlessly interface with AutoCAD software, enabling data exchange in DXF format. This compatibility promotes collaboration between measurement and design teams, expediting the integration of measurement data into the design process.

Efficient Post-Measurement Processing: The instrument supports direct editing within AutoCAD, facilitating the integration of measurement results into design documents and expediting subsequent processing steps.

Applications:

The two-dimensional measurement instrument finds widespread use across various sectors, making it an invaluable tool for quality assessment and precision measurement. Notable applications include:

Metal Dome Diameter Measurement: Accurate measurement of metal dome diameters is crucial for ensuring optimal performance and functionality.

Metal Dome Array Sizing: The instrument excels in determining the precise dimensions of metal dome arrays, critical components in tactile switches and user interface systems.

Mold Evaluation: For manufacturers producing metal domes and dome arrays, the instrument plays a pivotal role in assessing mold dimensions, contributing to consistency and reliability in production.

In conclusion, the two-dimensional measurement instrument signifies a leap forward in precision measurement technology. Its multifaceted capabilities, seamless integration with design software, and intuitive functions empower operators and manufacturers to achieve unparalleled levels of accuracy and quality in their products. As industries continue to demand ever-greater precision, this instrument stands ready to embrace challenges and reshape the landscape of precision engineering.

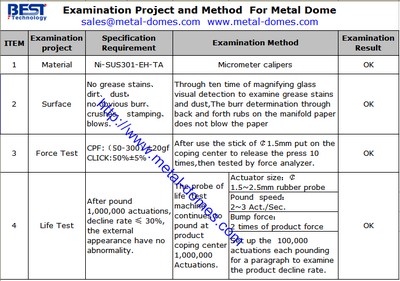

Best Technology is a company dedicated to product quality and relentless pursuit of excellence. We engage in batch production based on customer orders, ensuring rigorous quality checks throughout the production and shipment processes. Our commitment is to deliver satisfactory products to our customers. If you have any inquiries or requirements related to metal domes, feel free to reach out to us for expert consultation!