Domes are important metal components in membrane switches and are widely used in various products. Currently, many products utilize domes in diverse ways. Especially in flexible circuits, domes are used as elements to provide tactile feedback, commonly incorporated into membrane switches. By leveraging the conductivity of metal domes, the switch’s two poles are connected when the dome is pressed, and the dome’s rebound provides tactile feedback to the operator.

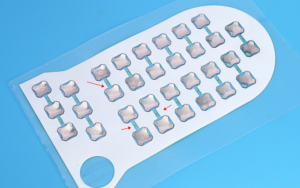

Common types of metal domes include circular, triangular, rectangular, and four-legged domes. To ensure smooth contact and increase travel, as well as to overcome friction between the bottom edge of the dome and the substrate during dome action and facilitate venting, three equidistant supporting dots are often embossed on the edges of circular and triangular domes. In addition to shape-based classification, modifications can also be made based on the dome’s outer dimensions, operating force, travel height, and material thickness. Best Technology offers a variety of dome specifications to meet various customer needs.

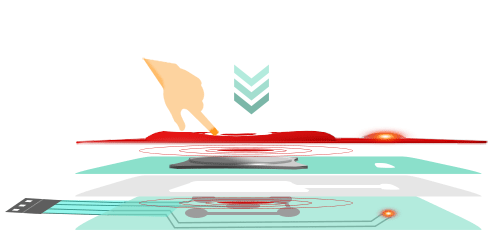

Metal domes are primarily used in rigid membrane switches, such as printed circuit boards, fully leveraging the three main characteristics of domes: conductivity, rebound, and tactile feel. In flexible membrane switches, metal domes are mainly used to provide tactile feedback. However, there are some downsides, such as the gap between the dome’s travel and the switch’s contact travel, which can cause a lack of synchronization between the dome’s action and the switch’s response. In flexible circuits, tactile feedback can also be achieved by creating a domed structure within the circuit layer. Best Technology has advanced equipment and processes to ensure uniform and excellent tactile feedback.

The selection of dome force should consider the size and weight of the whole device. For large devices with substantial weight and stability, membrane switches with more tolerant domes are preferable. For smaller or lighter instruments, lighter dome force should be selected to prevent device vibrations during switch operation.

Considering the operating direction, machines operated vertically can tolerate domes with greater force, while machines operated horizontally should prefer lighter dome force. Otherwise, excessive force during operation can cause displacement.

Regarding operating frequency, excessive dome force can slow down the operation, leading to operator fatigue. For switches with frequent use, it is essential to choose domes with lighter force.

When designing dome force, it is essential to consider the application scenario and design the dome force accordingly. Best Technology has extensive experience in designing and producing metal domes and can tailor them to meet customer requirements. Customization services are also available. If you have any metal dome needs, please feel free to contact us for consultation.