When it comes to manufacturing metal dome arrays, we at Best Technology pride ourselves on adhering to industry standards and using high-quality adhesive tape, with data sheets (hyperlinks, attached specifications) as our guiding reference. However, in certain cases, metal dome arrays may fail to adhere firmly, prompting us to explore the underlying reasons behind this issue.

Analyzing the Specific Reasons:

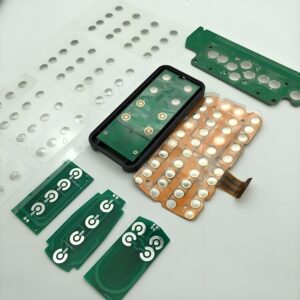

High Force and Stroke Requirements: Some metal dome arrays are custom-designed to meet specific customer demands, such as utilizing 12.2mm four-leg domes with a force of 400g and a stroke of 0.60mm or more. Meeting these high-force and stroke requirements can pose challenges in achieving optimal adhesive strength.

Insufficient or Excessive Adhesive Tape: The amount of adhesive tape applied to the customer’s drawings and specifications may not be adequate. It is generally recommended to maintain a minimum distance of 2.0mm to ensure proper adhesion.

Variations in Viscosity Tolerance: Each batch of materials used during manufacturing may exhibit different viscosity tolerances. When combined with the factors mentioned above, a lower limit viscosity tolerance can lead to weaker adhesion.

To address these issues, we have implemented measures to ensure that our standard metal dome arrays seldom encounter such problems. For cases requiring special specifications, we have integrated more robust adhesive tapes, such as the reliable 3M adhesive, to enhance the adhesion performance of specific dome array configurations. However, one drawback of using stronger adhesive materials is that they may not be easy to tear after sticking. Therefore, it is essential to carefully position the metal dome arrays during application to achieve the desired results effectively.

Metal Dome Application Scenarios:

Seamless Integration in Consumer Electronics: The innovative metal dome installation finds its ideal application in consumer electronics, ensuring seamless integration into smartphones, laptops, gaming consoles, and more. This cutting-edge technology guarantees clear tactile feedback and improved responsiveness for buttons and switches, elevating user interactions to new levels of satisfaction.

Advancements in the Automotive Industry: Automotive manufacturers can benefit significantly from this breakthrough. The precise installation process allows metal dome arrays to be seamlessly integrated into steering wheel controls, infotainment systems, and dashboard interfaces. Drivers and passengers will experience enhanced tactile responses and smoother functionality, enhancing the overall driving experience.

Healthcare and Medical Devices: In the healthcare sector, the metal dome installation method paves the way for improved tactile feedback in medical devices. From touch-sensitive control panels in medical equipment to handheld devices for patient monitoring, this technology ensures precise and reliable inputs, increasing overall efficiency in critical healthcare scenarios.

At Best Technology, our primary goal is to provide high-quality metal dome arrays that cater to a wide range of customer demands. By continuously refining our processes and materials, we ensure that the issue of insufficient firmness is kept to a minimum, offering our customers reliable and durable products. The seamless integration and customized services for metal dome arrays in various industries enhance user experiences and solidify our commitment to customer satisfaction.