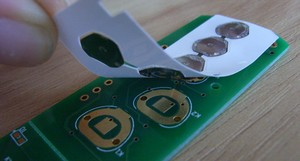

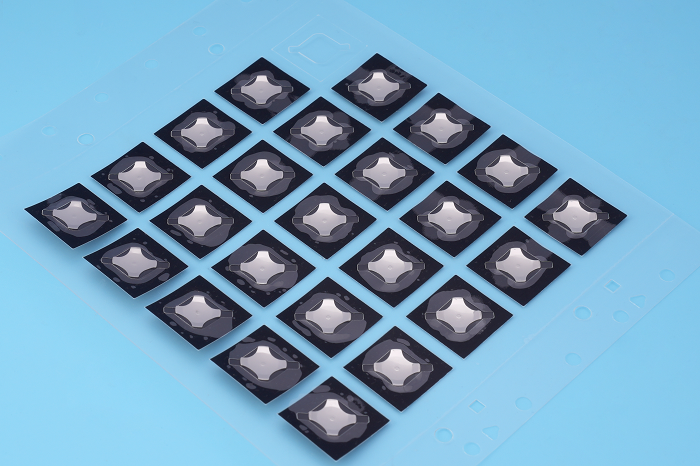

In the world of mechanical engineering, metal domes play a crucial role in various applications. These small, circular metal components are widely used in keyboards, touchpads, and other input devices to provide tactile feedback and enhance user experience. One important aspect of metal domes is their travel distance, which determines the amount of force required to activate them. In this article, we will delve into the intricacies of calculating the travel of metal domes and explore the factors that influence it. So, let’s dive in and unlock the secrets of metal dome travel!

What is the Travel of a Metal Dome?

Before we delve into the calculation process, it’s essential to understand what we mean by the travel of a metal dome. The travel refers to the moment when the metal dome starts to move to the moment when it contacts the contact surface, the distance of the metal domeâs action in this period is what we call travel. It is an important parameter that directly affects the tactile feedback and user experience.

Factors Affecting Metal Dome Travel

Several factors influence the travel distance of metal domes. Understanding these factors is crucial for accurate calculations. Let’s explore the key elements that affect the travel of metal domes:Â

1. Dome Geometry

The shape and dimensions of the metal dome greatly impact its travel distance. Different dome profiles, such as round, four-leg, and cross-dimple, have varying travel characteristics. Usually the height of four-leg metal dome and triangle metal dome is higher than round metal dome, and the click feeling is better than round dome as well.

2. Material Properties

The material used to manufacture the metal dome plays a significant role in its travel. Factors like the thickness, elasticity, and hardness of the material influence the travel distance.Â

3. Actuation Force

The amount of force required to activate the metal dome affects its travel. Higher actuation forces result in shorter travel distances, while lower actuation forces allow for more significant travel.

When the force is larger, the height will be relatively higher and the material thickness increases, too, so the travel increases as well. Â

4. Dome Size

The size of the metal dome is directly proportional to its travel distance. Larger domes generally have longer travel distances compared to smaller ones.

5. Environmental Conditions

The operating environment, including temperature and humidity, can affect the travel of metal domes. Extreme conditions may cause variations in the travel distance.

How to calculate the travel distance of metal dome?

Now we have a clear understanding of the factors that affecting the travel distance of metal domes, now letâs trying to calculate the travel.

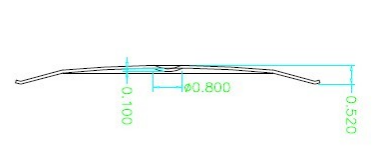

Generally, the travel = height – material thickness – the depth of the central dimple. For example, the metal dome height is 0.52mm, material thickness is 0.10mm and the depth of the central dimple is 0.05mm, how much is the travel? Letâs calculate it with this equation: travel =height – material thickness, so the travel is 0.52-0.10-0.05=0.37mm. Well, if your metal dome does not have a dimple, then the travel = height â material thickness.

Calculating the travel allows designers to ensure that the click feeling meets their desired specifications and user expectations. Best Technology is a expert manufacturer in metal dome, dome array and OCA products, we have 20 high-speed precision metal dome punching machines with a daily capacity of 4 million pieces and monthly production capacity of 100 million pieces that can meet your bulk orders or mass production. You can no worry about the lead time and product quality. Just feel free to contact us or leave your message below if you have inquiries.