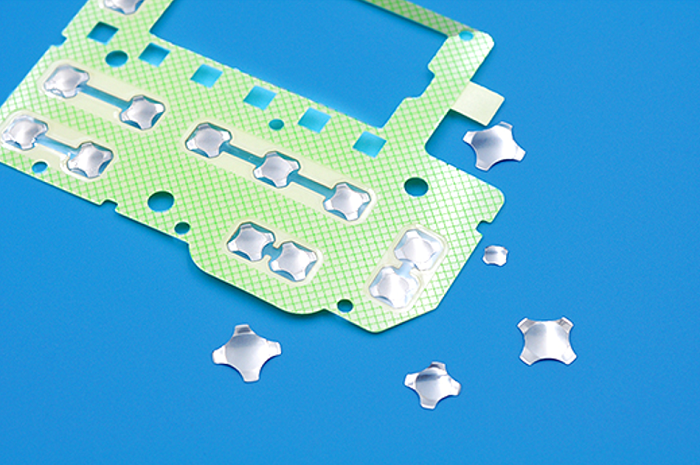

Metal dome arrays are widely used in electronic devices, providing tactile feedback and reliable switch activation. However, there are instances where the metal dome array may not secure firmly as desired. In this article, we will discuss the reasons behind this issue and analyze the factors that contribute to it.Â

1. High Force and Stroke Requirements

One reason for the metal dome array not being firmly secured is the high force and stroke requirements specified by the customer. In certain cases, customers may require metal domes with high force and stroke, such as 12.2mm four-leg domes with a force of 400g and a stroke of 0.60mm or above. These requirements can pose challenges in achieving a strong adhesive bond due to the nature of the materials involved.

2. Inadequate or Excessive Adhesive Tape

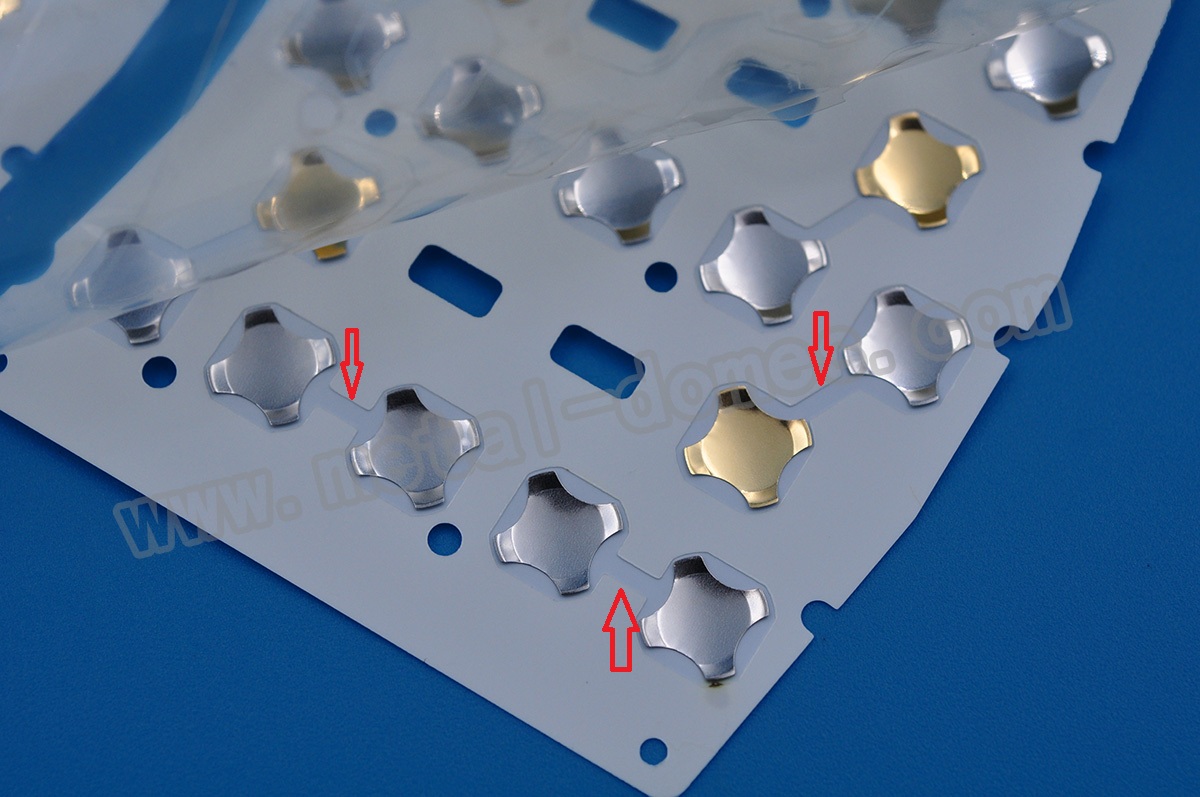

The adhesive tape used for the metal dome array may not be properly aligned with the customer’s drawings and specifications. It is crucial to ensure that an appropriate distance of at least 2.0mm is maintained between the dome array and the adhesive tape. Insufficient or excessive adhesive tape can result in a weaker bond and compromise the firmness of attachment.

3. Variations in Material Viscosity

Each batch of materials used for the metal dome array may have variations in viscosity tolerance. If the viscosity tolerance of the materials goes to the lower limit and combined with the factors mentioned earlier, it can affect the firmness of the adhesive bond. Lower viscosity materials may not provide the desired level of adhesion, leading to a less secure attachment. To address these issues, certain steps can be taken:

- Consider using a more viscous adhesive tape, such as 3M, for metal dome

arrays with special specifications. This can help improve the adhesion strength and ensure a firmer attachment.

- Ensure that the adhesive tape is applied correctly and in right quantity to

maintain the recommended distance between the dome array and the tape.

- Monitor and control the viscosity tolerance of materials to ensure consistency in adhesive performance across different batches.

It’s important to note that such problems are uncommon with standard metal dome arrays. However, for specific requirements and higher force/stroke specifications, using stronger adhesive materials and following precise application techniques can help mitigate the issue. It’s essential to apply the adhesive tape accurately in one attempt since it may not be easy to reposition or remove after sticking.Â

FAQsHere are some frequently asked questions related to the issue of metal dome arrays not securing firmly:Â

Q1: How can I ensure a firm attachment of metal dome arrays in my product design?

A1: To ensure a firm attachment of metal dome arrays, consider the following:Â

1) Use adhesive tapes that are suitable for the specific force and stroke requirements.

2) Properly align the adhesive tape with the dome array according to the recommended distance.

3) Optimize the viscosity of the adhesive material to maintain consistent adhesion across batches.

4) Follow precise application techniques and ensure accurate positioning during the attachment process.

Q2: What should I do if the metal dome array does not secure firmly in my product?

A2: If you encounter issues with the firm attachment of metal dome arrays, you can try the following solutions:Â

Evaluate the force and stroke requirements and consider using stronger adhesive materials.

Double-check the alignment and quantity of adhesive tape to ensure it meets the recommended specifications.

Consult with the manufacturer or supplier for guidance on resolving the issue.By considering these factors and taking appropriate measures, you can enhance the firmness of attachment for metal dome arrays and ensure their reliable performance in your product.Â

Q3: Are there any alternative methods to improve the firmness of attachment for metal dome arrays?

A3: Yes, there are alternative methods you can explore to improve the firmness of attachment for metal dome arrays:Â

Consider using mechanical fasteners in conjunction with adhesive bonding for added stability.

Explore the use of specialized bonding techniques, such as ultrasonic welding or soldering, depending on the specific application requirements.

Collaborate with the manufacturer or supplier to explore customized solutions tailored to your specific needs.

It’s important to evaluate the feasibility and suitability of alternative methods based on the specific application and requirements of your product.Â

Conclusion

By considering the recommended solutions, exploring alternative methods, and collaborating with experts, you can improve the firmness of attachment for metal dome arrays, ensuring optimal performance in your electronic devices. If you still have some confuses, welcome to contact us at sales@metal-domes.com.