Metal domes play a critical role in various electronic devices, providing tactile feedback and switch activation. The longevity and durability of these components are essential considerations for manufacturers and product designers. To ensure optimal performance and longevity, it is crucial to understand the factors that can affect the lifetime of metal domes. In this article, we will explore these factors in detail and provide insights into maintaining the longevity and reliability of metal domes.

Material Quality

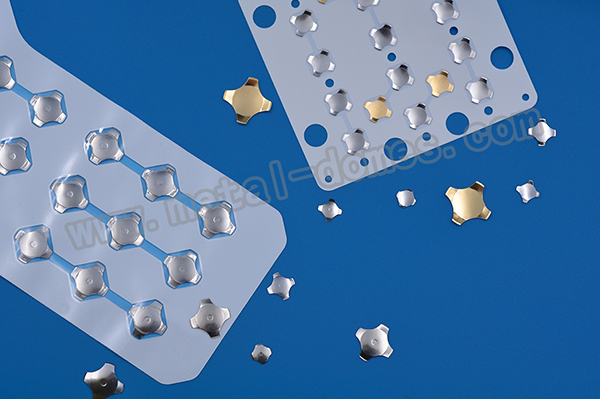

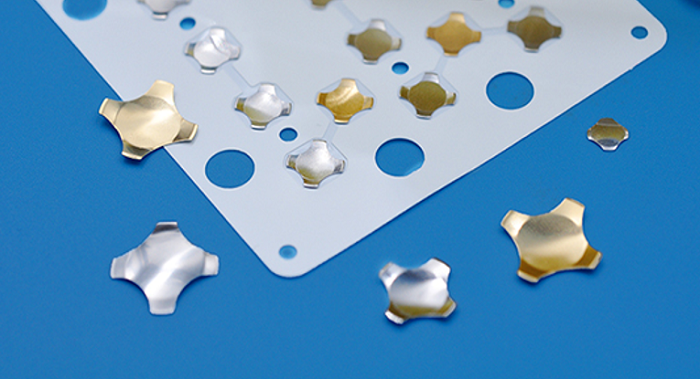

The quality of the materials used in manufacturing metal domes is a fundamental factor influencing their lifespan. High-quality materials, such as stainless steel or nickel-plated stainless steel, offer exceptional resistance to corrosion, wear, and environmental factors. By using superior materials, manufacturers can ensure that the metal domes withstand the test of time, preventing premature failure or degradation.

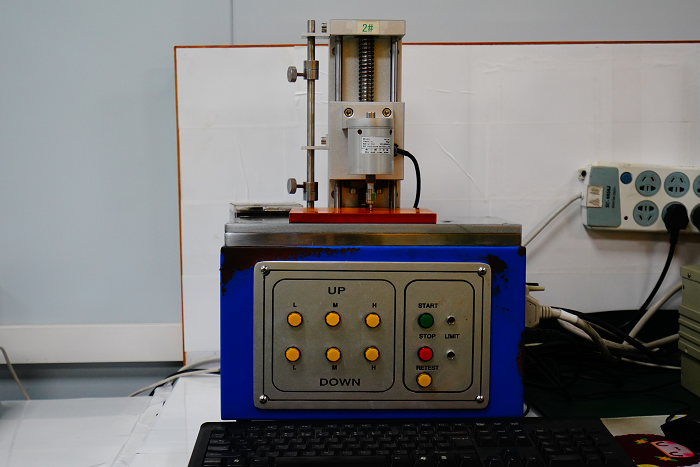

(Life tester)

Environmental Conditions

The environmental conditions in which metal domes are used have a significant impact on their lifespan. Extreme temperatures, high humidity, exposure to chemicals or solvents, and mechanical stress can all affect the performance and durability of metal domes. To mitigate these risks, it is essential to consider the specific environmental conditions and select metal dome materials and coatings that can withstand these challenges. Proper protection against environmental factors ensures that the metal domes remain functional and reliable over an extended period.

Actuation Force and Cycling

The actuation force and cycling of metal domes also play a crucial role in determining their lifespan. Actuation force refers to the pressure required to activate the metal dome and register a keystroke. Excessive or inconsistent actuation force can lead to fatigue and deformation of the metal dome, reducing its lifespan. Similarly, frequent cycling or excessive use can cause mechanical stress and wear, potentially resulting in the failure of the metal dome over time. Striking the right balance between precision and longevity is essential to maximize the lifespan of metal domes.

(Force tester)

Coating and Surface Treatment

To enhance performance and durability, metal domes often undergo various surface treatments and coatings. These coatings provide protection against abrasion, wear, and environmental factors. However, the quality and integrity of the coating are crucial in determining the lifespan of the metal dome. A high-quality coating effectively shields the metal dome from corrosion, moisture, and other potential sources of damage, prolonging its lifespan and preserving its functionality.

Operating Conditions and Maintenance

The operating conditions and maintenance practices employed for electronic devices significantly impact the lifespan of metal domes. Proper usage, adherence to recommended operating parameters, and regular maintenance are vital to prolong their longevity. Applying excessive force or subjecting the metal dome to impacts, maintaining a clean operating environment free from contaminants, and conducting routine inspections can contribute to the prolonged lifespan of metal domes.

Design and Manufacturing Quality

The design and manufacturing quality of the overall product or device incorporating metal domes play a crucial role in their lifespan. Proper placement, alignment, and integration of metal domes within the device are essential to ensure optimal performance and longevity. Manufacturing processes that adhere to strict quality control standards, including appropriate handling and installation of metal domes, reduce the risk of premature failure and contribute to their extended lifespan.

FAQs

Here are some frequently asked questions about the factors affecting the lifetime of metal domes:

Q1: Can additional protective measures extend the lifespan of metal domes?

A1: Yes, additional protective measures such as conformal coatings, encapsulation, or sealing can be applied to metal domes to enhance their resistance to environmental factors and increase their lifespan. These protective measures provide an extra layer of defense against moisture, chemicals, and physical damage, ensuring the longevity and reliability of the metal domes.

Q2: Are metal domes suitable for outdoor applications?

A2: Metal domes can be suitable for outdoor applications depending on the material used and proper protective measures. Stainless steel or coated metal domes with weather-resistant coatings are more resilient to environmental factors such as temperature fluctuations and moisture. Additionally, proper sealing and protection against dust and debris can further enhance their suitability for outdoor use.

Q3: How can I ensure the longevity of metal domes in my product design?

A3: To ensure the longevity of metal domes in your product design, consider the following: Choose high-quality materials with excellent resistance to corrosion and wear.Select appropriate coatings or surface treatments to enhance durability.Design the product with proper alignment and integration of metal domes.Consider the operating conditions and implement preventive measures to minimize stress and wear.Follow recommended maintenance practices and perform routine inspections.By incorporating these considerations into your product design, you can maximize the lifespan and reliability of metal domes.

Q4: Can I reuse metal domes in case of product repairs or upgrades?

A4: It is generally not recommended to reuse metal domes once they have been installed in a product. During the removal process, metal domes can experience deformation or damage, which may affect their performance and reliability. It is best to replace metal domes with new ones to ensure optimal functioning and longevity of the product.

Q5: Are there any industry standards or certifications for metal domes?

A5: Yes, there are industry standards and certifications that ensure the quality and reliability of metal domes. For example, ISO 9001 certification ensures adherence to quality management standards. Additionally, manufacturers may comply with specific industry standards, such as RoHS (Restriction of Hazardous Substances) or REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), to meet environmental and safety regulations.

The lifespan of metal domes is influenced by various factors, by understanding these factors and implementing appropriate measures, we can ensure the longevity and reliability of metal domes in their end-applications. Best Technology specializes in the production, sales and service of metal domes, dome array, light guide film and OCA products, you are welcome to contact us at any time for any questions.