Metal domes, also known as tactile domes or snap domes, are small, dome-shaped components used in membrane switches, keypads, and other devices requiring tactile feedback. These domes are typically made of stainless steel due to its excellent mechanical properties and corrosion resistance. Among the different grades of stainless steel available, SUS 301 and SUS 304 are widely used for manufacturing metal domes.

Some of our customers are always curious about the differences between SUS 301 and SUS 304 of metal dome. And they will ask the raw material of our metal domes, why you do not use SUS 304? Can you use SUS 304 to make this metal dome? Today I will introduce the differences between two of them, hope this will helpful for you to select the most suitable material for specific applications.

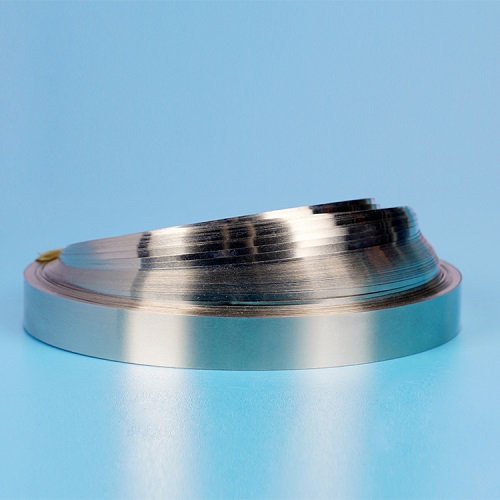

(Raw material of metal dome)

Composition difference of SUS 301 & SUS 304

Actually, both of them belong to the Martensitic stainless steel, but they have a slight difference of their compositions. The main difference is that the content of Cr and other elements is different, so the performance is different.

In the current market, the material mainly used to produce metal domes is SUS 301 in the domestic, while what is used more is SUS 304 in Hongkong, and both are used in aboard. Besides, people will choose the most suitable for the factory processing technology, the ability of the material, the use of different technologies, so that it will achieve the desired best effect, such as lifetime, click feeling, etc.

- SUS 304 (stainless steel): it is the most widely used stainless steel.

Because it contains Ni, it has better ability of corrosion-resistant and heat-resistant than Cr steel, and has low-temperature strength. Therefore, its mechanical properties are great, and its work hardening is very large. It will not be hardened after heating treatment, non-magnetic, with good strength and less elasticity. It is often used with a thickness of 0.4t ~ 1.0T.

- SUS 301 (stainless steel): Cr (chromium) composition is lower than SUS

304. And the corrosion resistance is poor, but cold working can get a very high degree of tension and hardness. Because of its good elasticity, so at present, it is widely used in laptop to play a role of anti-EMI. Its most commonly used thickness ranges from 0.4T ~ 0.07T.

The material properties between SUS 301 & SUS 304

Different composition means they have different properties and result in the different application and fields that they can be used in.

- SUS 301: Suitable for elastic use, high carbon content, high hardness, not easy to elastic fatigue, poor ductility, not easy to stretch.

- SUS 304: Not suitable for elastic use, low carbon content, low hardness (soft)

But these material properties are not applicable in all situations.

For example, when the hardness of the two materials is close or the same, which one should be chosen? Such as SUS301 3/4H and SUS 304 H?

In this case, we should combine all aspects to consider. Although their hardness is the same, when they are used in the elastic products, SUS 304 H is more likely to have an elastic fatigue, so SUS 301 3/4H is more suitable.

In addition, the thickness of the material also will affect the hardness tolerance (the thicker the material is, the greater the tolerance will be.)

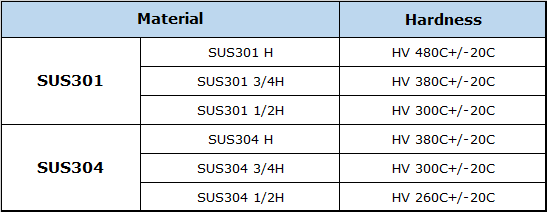

Below are some properties comparisons between SUS 301 & SUS 304.

1.Hardness comparison:

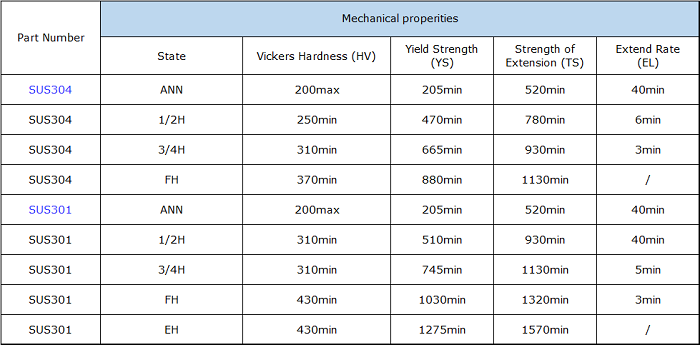

2.Mechanical property of SUS 301 & SUS 304:

This is the end of this sharing, after reading this article, if you still have some questions about them, welcome to leave a message or call us +86-755-2909 1601, or email us sales@metal-domes.com at any time.