In our last article, we shared the assembled method for metal domes, but there are still some customers curious about the mounted way about Triangle metal dome. So today we will show you the detailed method when we assemble the triangle domes, hope this is helpful solution for your projects.

Below are the common specifications for the triangle domes in the market, they can be classified by four types — no leg, short leg, middle leg and long leg, each dome has different leg length. Best Technology has 0.8mm, 1.5mm and 3.0mm leg length for triangle snap domes, and other special length like 2.5mm also contact us.

Triangle Metal Dome

Below are the main questions that customers are more concerned, hope this can

Q1: Can I solder a triangle metal dome with legs on PCB directly?

A: It is not recommended to solder triangle domes on the PCB or FPC directly. Because triangle dome plays a conductive circuit function on the circuit board, the domes will have a certain extension to the four sides when press it down. If solder it directly on the PCB, two legs of the domes will be fixed, when press it down, the metal dome canât extend around the sides, the pressure strength will be increased as well. So that the life time of metal dome will be shorten and some characteristics canât perform well when apply to the end-applications, which will cause the âdead keyâ, poor clicking feel, unstable strengthen and some other issues.

Q2: Do you have any better method to fix the triangle metal dome?

A: Of course. The common metal domes which used on FPC/PCB mostly are triangle dome, circle dome and four-leg metal dome. We can fix it as following ways according to the different needs.

1.Insert two legs of triangle dome into the plug-holes on PCB, and bend the two legs. â This is the most popular solution.

But it has an obvious drawback that it is easy to shake and spend a lot of human time, and it must has plug-in holes on the PCB to insert the legs.

We can choose suitable leg length according to the board thickness. In generally, the common thickness for printed circuit board are 0.8mm, 1.0mm, 1.2mm and 1.6mm, the corresponding leg length are 0.8mm, 1.5mm, 2.4mm (special) 3.0mm in Best Technology.

Triangle metal dome insert in PCB

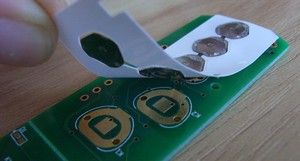

2.Stick triangle dome with a 3M adhesive tape. The disadvantage is if the tape doesnât have a good stickiness, then the metal dome is easy to be misaligned.

3.Make the triangle metal dome as dome array. Dome array is easy and convenient to stick on the PCB, but the cost will be a little more than other two methods. At present, dome array (DA) is widely used in many buttons, such as keypad, keyboard, mobile phoneâŚ

Triangle dome array with PCB

Q3: We have limited space which only enough for one metal dome, and there are too many components around the side, what should we do?

A:You can try to use soft hot melt adhesive fix the metal dome, so that triangle dome enables extend around when press the domes down while wonât lead any potential risk to the function, why not! It is the best way that we recommend when must solder metal dome on the PCB or flex circuits.

Above are the common questions and solutions we faced and solved when communicated with our customers, if you have any other good methods that can mount the triangle domes on the circuit boards easily, welcome to contact us at sales@metal-domes.com. And also, if you still have some questions that can be solved by these ways, just feel free to let us know, our experienced sales will solve for you timely.