There are so many different types of metal dome arrays, due to the similar shape, they are hard to distinguish quickly in the first time. Here, Best Tech sharing some methods to help you to recognize the various dome arrays, let’s get started.

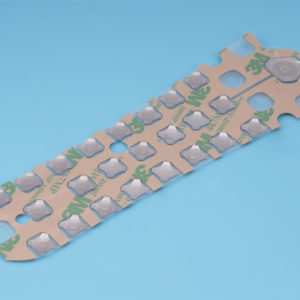

First of all, we should know how many types of dome arrays in the market. Currently, what most commonly snap dome arrays are as followings:

- Single layer dome array

- Double layer dome array

- EMI printing dome array

- Rubber glue dome array

- LGF dome array

In these five kinds of dome arrays, the single layer and double layer dome array are most difficult to recognize since they are almost in the same shape in visual. But if we observe their structure by a simple tweezers, then you will find the way fleetly.

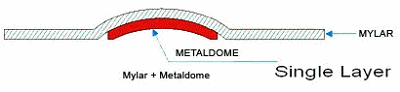

For the structure of a single layer dome array, the metal sheet is located

under Mylar (a layer of PET adhesive material with glue) and it has some vent holes to ensure the basic click feeling and using. For better understanding, you can see below structure diagram:

(Single layer dome array)

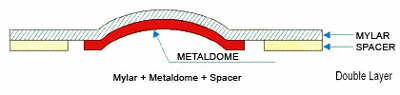

Double layer metal dome array is somehow similar to single layer type by

means of metal dome contacts attached under Mylar as well. But the difference is that, in this type, an extra spacer is attached under the metal dome contacts. Air paths which function like air holes in single-layer, helps provide good click-feeling when dome contacts are pressed. Besides this effect, air paths help reduce the potential risk for PET film being damaged by metal dome contacts’ burr and block dust coming into PET films. So, double layer metal dome array is composed of metal dome, spacer and mylar, see below diagram for better understanding.

(Double layer metal dome array)

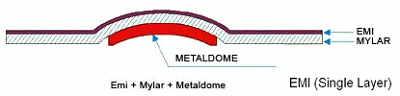

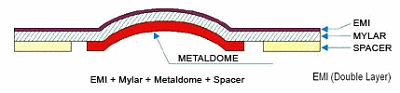

EMI dome array is printing a layer of silver paste or silver carbon on the top of mylar material functionality as an electrostatic discharge control (ESD). Same as normal FR4 PCB, EMI dome array can be classified into single layer EMI printing and double layer EMI printing dome array. Whether single or double layer, the EMI are printing on the top side on the whole product. Below is the structure of EMI printing dome array.

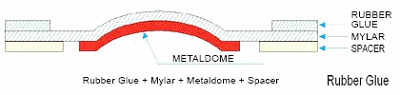

Rubber glue dome array manifested as one layer of Rubber Glue added on top of the Mylar or EMI. It performs special plastic performance and can be tightly stick on Keypad or PCBs. Because material of adhesive is Silicone, so it also named Silicon or Acrylic PSA adhesive tape, here you can see the datasheet of one of normal rubber glue material used in our top adhesive dome array.

The rubber glue dome array consists of a layer of rubber glue, Mylar, spacer and a layer of metal dome. So actually, the difference between EMI dome array and rubber glue is the top layer material, you can see below structure.

LGF dome array is a new design in dome array market, which add a layer of LGF material on the top of normal dome array. LGF full name as Light Guide Film, just as its name implies, it is a film which can achieve better light distribution. It is very easy to distinguish since the LGF always shows in a transparent film (sometimes it also shows white or grey color.)

Same as above dome arrays, the basic materials are Mylar, Spacer, metal dome, and this dome array add an extra LGF on the top of Mylar, details please see below.

Above are the five popular dome arrays in Best Technology. And if you have some other special design which not belong to these five types, we also can make for you, since we have custom dome array service.

In a word, by means of a small tool we can recognize the dome arrays very easily, hope this post will make you sense the way to distinguish various dome arrays. If you still have some doubts, warm welcome to contact us at the first time, we are always here!