We always get feedback from customers that the click of dome switch or metal dome is not good after assembly on PCB, what reasons cause this issue? That’s what they care about most. Today I will analyze it from the following reasons.

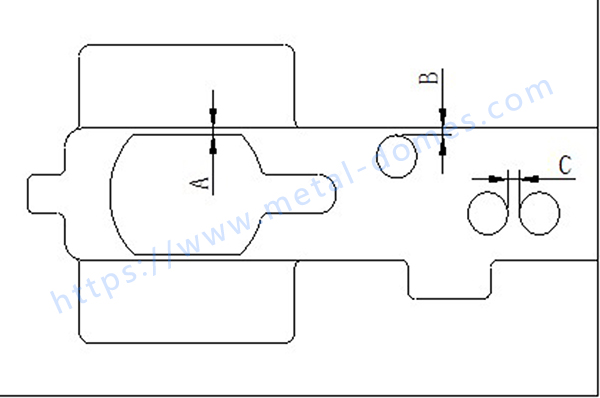

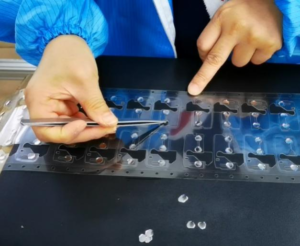

- There is an 0.15mm assembly tolerance when assemble metal dome onto PET adhesive

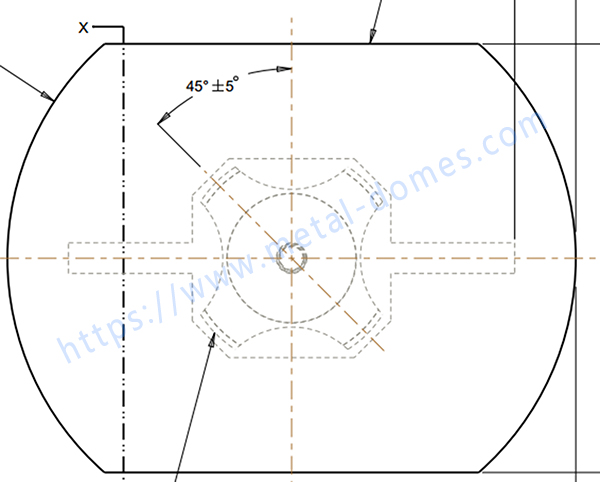

- If place four legs or triangle metal dome, there will also be a 5 percent angular tilt tolerance.

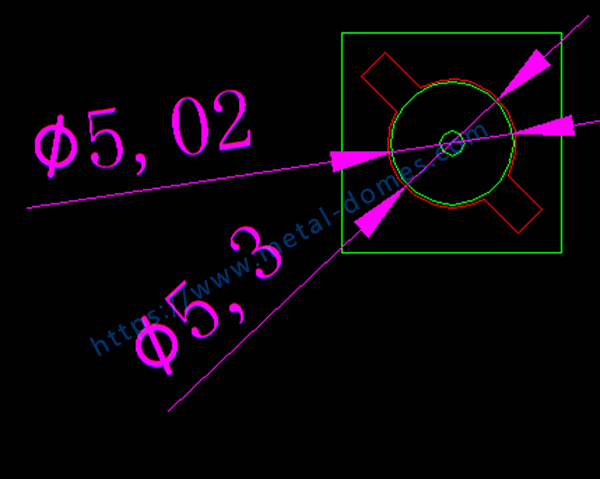

- If place round metal dome, the diameter of hole on spacer would be 0.3mm larger than metal dome, then could ensure unilateral tolerance of 0.15mm

- There is a assembly tolerance when customer place dome array on PCB (print circuit board)

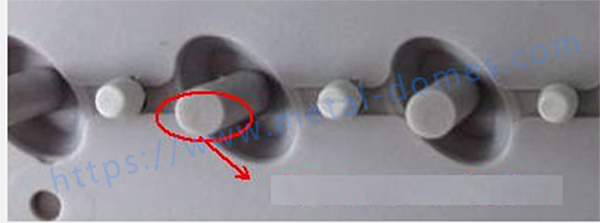

- The press key or press rubber key is very large, exceed 30% of contact surface of metal dome from center, lead to hard to press and influence the click.

All above factors would influence the click of snap dome, so we need to take these factors into account when we produce. Avoid trouble in next step.

If you still have any question after read, please feel free to contact us, we are here always and would solve your issue and provide our help to you.