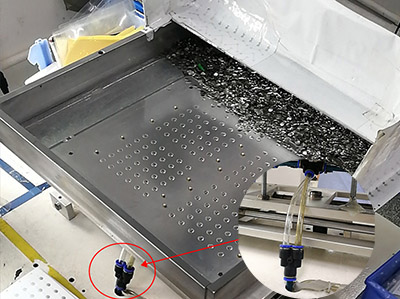

Metal domes underneath membrane switches help keep the membrane from remaining in contact with the key at all times. The domes also help conduct the electricity through the keypad, sending a clearer signal to the circuits of the unit, preventing misfiring and other problems that can occur when the circuitry is out of alignment. The dome design also retains a high level of buoyancy, which keeps the dome and key popping back into place after every press. These little metal domes are a vital part of any membrane-based design, and most membrane switch systems use domes for the above-mentioned reasons.

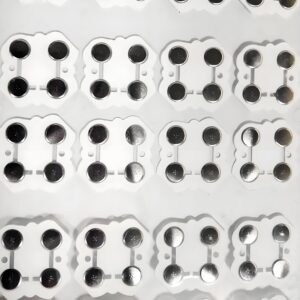

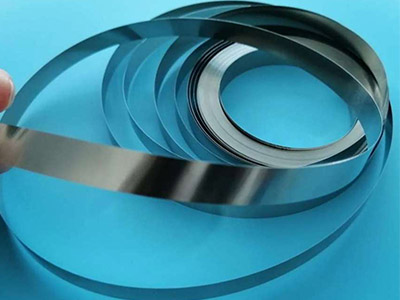

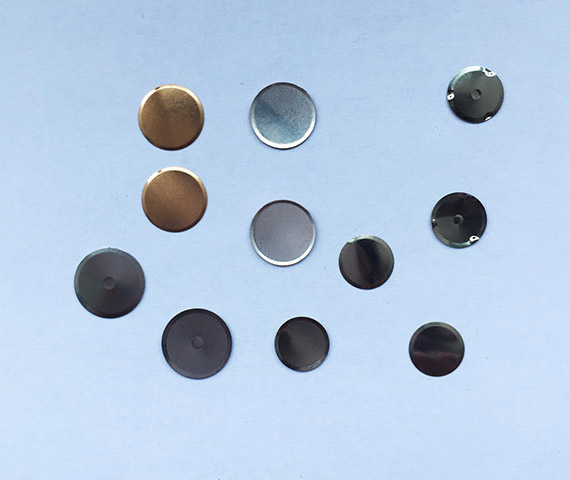

However, there has been a problem with the standard dome design for membrane keypad. Most domes are constructed with a raised, rounded bubble that reaches above the corners of the strip of metal. The corners always rest on the keypad, keeping the dome from coming into contact with the circuit board unless the dome in pushed. The metal ÔÇťfeetÔÇŁ on the button must stay in place securely, otherwise┬áthe domes can shift and cause problems with the board.

Unfortunately, with extended use, many of these domes will shift or move over time. This makes them difficult to use, and it is also difficult to fix this issue without replacing the entire keypad. The best solution to this problem has been the addition of a second dome or dimple placed in the center of the original dome, which can reduce the need for a keypad actuator. The actuator normally controls the keys as they are pressed to ensure that they only apply pressure to the designated key, rather than to surrounding keys or buttons. The dimple on the surface of the dome helps keep the key in proper alignment and makes precise accuracy in the placement of the dome or keypad actuator unnecessary.