The reason why the metal dome is pressed but do not rebound maybe related to the operational environment as well as the using habits of the operators. The metal dome must be used in a flat surface. It is a very long stroke if the metal dome is pressed on a concave surface, which is easy to cause anti-concave of the metal dome. And pressing the metal dome with a strong force will also cause anti-concave of it.

In addition to the above reasons, there is still another one: the metal dome has deformed.

As known to us, the metal dome will be deformed by the external force. There are several possibility will cause like that:

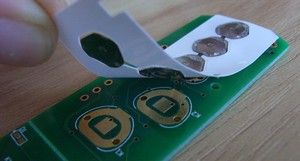

- The material is squeezed during transportation.

- The metal dome is stuck by the jig.

- Tweezers are used in the manufacturing process.

Now we have already know the reasons, but how to prevent? Details as below:

Preventive measures

- Using foam to wrap a few laps when the material is packed, then put it into the carton,sticking a fragile tag and ask the courier to take it carefully during transportation.

- Using tweezers to pick out the metal dome that is stuck by the jig.The metal dome should not be reused if it is stuck in the jig.

- In order to prevent the metal dome from deformation, using tweezersto clamp the metal dome should be lightly in the manufacturing process.

If you also would like to know further information of click feeling about metal dome, click here to read How to Calculate the Click Feeling of Metal Dome?