On every weekend, we will have a short meeting to check the statistics data of that week and we found out a very obvious trend in the shipment of our Four legs series metal domes, that is: “more smaller size, more high quality requirements, more packing methods”.

There’s a one time, when membrane switches were so hot in the market, the dome used in it was big diameter one such as 12.2mm, 8.4mm etc, and the force were 220gf, 280gf, and 320gf. As the touchscreen technology become popular, it seemed that few and few company used tactile metal domes, all of the guys turn to try the new tech.

In some important section, however, the vital switch have to be avoided of mis-handling by human hand or an incident, and touch screen cannot reach that goal, so tactile dome turn back to the top of desk. As people have gone through the experience of tactile dome and touch screen, they want to strike the right balance. Such being the case, some company designed the dome with smaller diameter with lower force but remain good click feeling, and Four legs series metal domes are the right choice for them.

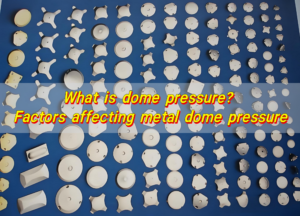

With its unique structure, Four legs series metal domes can have the best click feeling, and at the same time, we have add several supporting circle in our tooling so that there’re related circles, visible and unvisible, in our goods, to make sure high quality and long life cycles (over 1 million times).

There’s a common sense that “the smaller diameter dome is, the more difficult manufacturing will be”. With our special design, our 6mm and 7mm Four legs series metal domes have endure strict testing by our clients. Recently, we have becomed the supplier of metal dome for Emerson. We wish more customers can try our new small size metal domes, and to meet your various requirements.

In next article, we will discuss the requirement of packing method for Four legs series metal domes.

(to be continued)