As we know, the general packing of metal dome is in bulk, such as 1,000 pcs or 5,000 pcs per PE bag. This kind of packing has the lowest packing cost. But there’re also other kinds of packing methods, such as in tube, or on array and so on. Today we’ll talk about the tube packing of metal dome.

The metal domes are loaded inside of a certain shape of tube, via a special machine. And now, let take a glance at this special machine. Can you guess which kind of machine should be used in metal dome tube packing? Tell me your answer, maybe I can send you a Christmas gift. Haha ^_^ Or do you have special idea about the packing? If so, let me know, The big suprise is just for you!

Firstly, let’s name this machine “xxx feeder”, the follows are several kinds of them. Let’s find outÂ

Parts feeders are machines that orient parts so that robots or other automated processes can capture and use or package the parts or components. Applications range from packaging pills in the pharmaceutical industry to sparkplug production in the automotive industry. The main difference between parts feeders is their method of directing the feed.Â

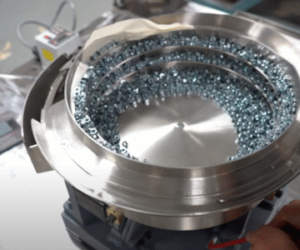

Vibratory bowl feeders are the most common type of parts feeders. The bowl has a helical track which climbs the inside wall of the bowl. Parts are dumped into the bowl that vibrates and turns. As the parts climb the track they encounter obstacles that orient the parts in a certain way. So that they can be easily used further down the line.

Centrifugal rotary feeders use a bowl that spins and forces parts to the outside of the bowl. At the outside edge of the bowl, the parts are channeled into receivers when the parts are in the right orientation. From the receiver, they go onto a track that moves the parts to the next stage of production. Centrifugal feeders are usually faster and less noisy than vibratory feeders. They also tend to mar parts less than other types of feeders.

Pneumatic feeders move and position parts by means of a pneumatic piston.The piston functions via hydraulic (liquid) pressure or an air-driven motor to force parts through a tube. These units are ideally suited to convey closures to capping machines, but are also applicable for handling many other small parts including liners, fitments, corks, capsules, etc.

The bowls of parts feeders are commonly available in two configurations, although custom bowl types are manufactured. Cascade bowls, also known as inside track bowls, are primarily used for feeding easily oriented parts like screws and dowels. They are often quieter and less costly than outside-track designs. Outside-track bowls are used when more intricate tooling is required for proper part orientation, for higher feed rates, or for multiple lines of feed. The outside track is pitched downward to improve the separation and orientation of the parts.

Programmable parts feeders are also available. They are more flexible than traditional parts feeders and may be programmed to change the way they isolate or orient parts. Programmable feeders are available in several different configurations ranging from programmable frequency of vibration in a traditional type of feeder, to sensor driven actuators that reorient parts. Robotic parts feeders that use sensors and manipulators to orient parts are also manufactured.

Okay, I think know you’ll know what a “feeder” is. So let continue our game:”Which one is suitable for tube packing of metal domes. Do you wanna get more? This article will be continued… …