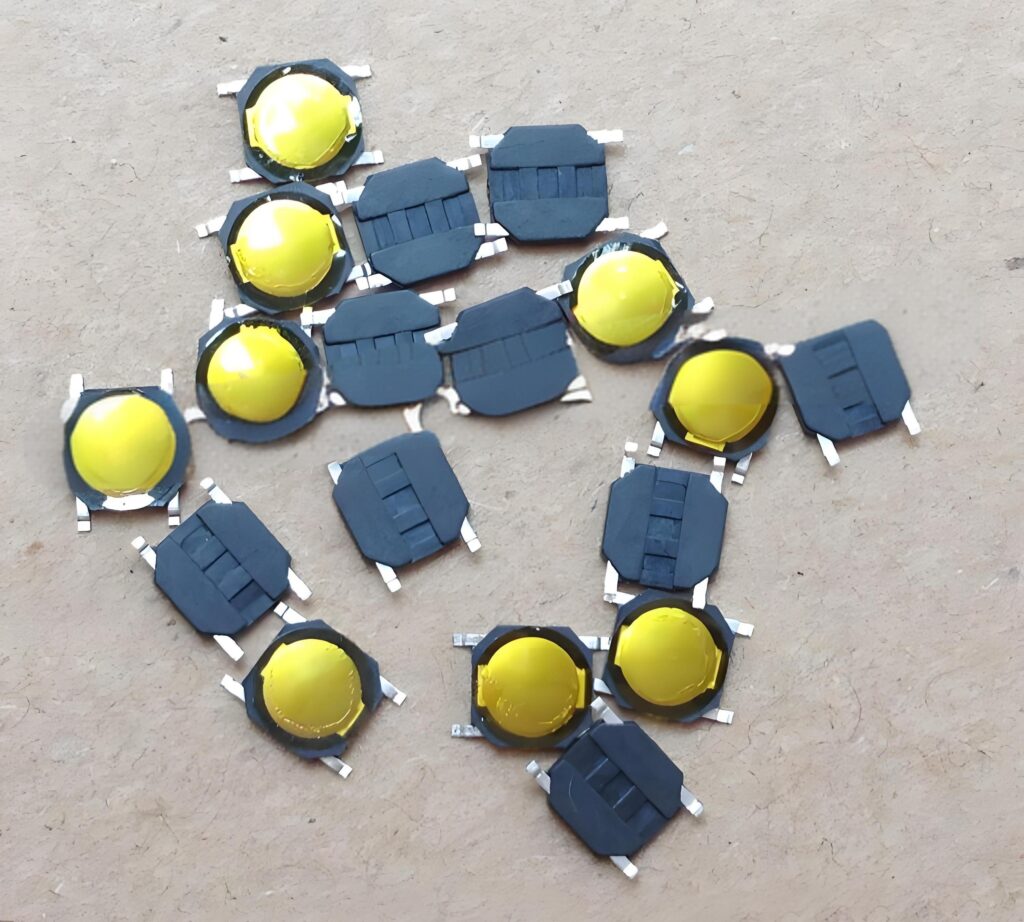

The tactile metal dome is connected to the PCB by pressing. When the dome is pressed, its conductive end forms an electrical connection with the corresponding contact on the PCB, thereby achieving circuit conduction. This connection method ensures the effective transmission of current signals while providing clear tactile feedback.

How do tactile metal domes make contact with PCB circuits?

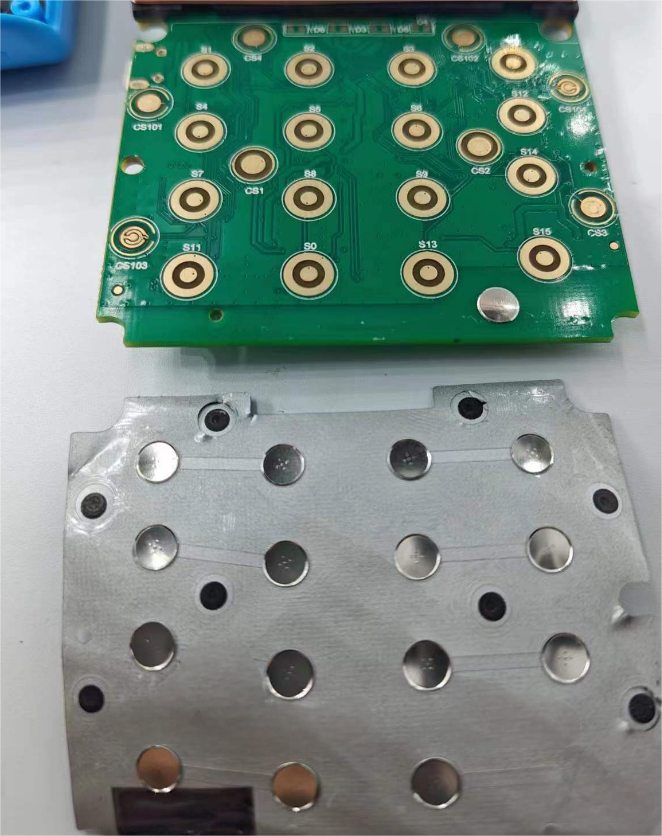

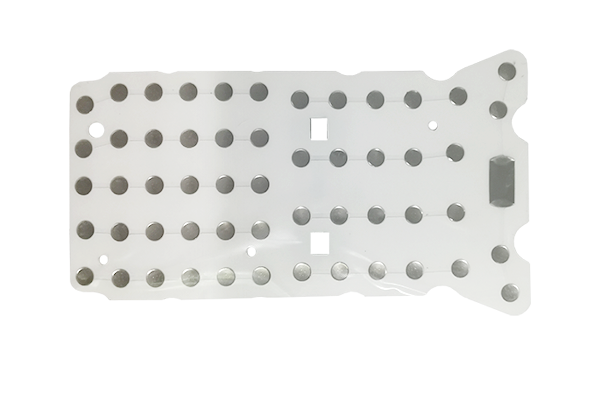

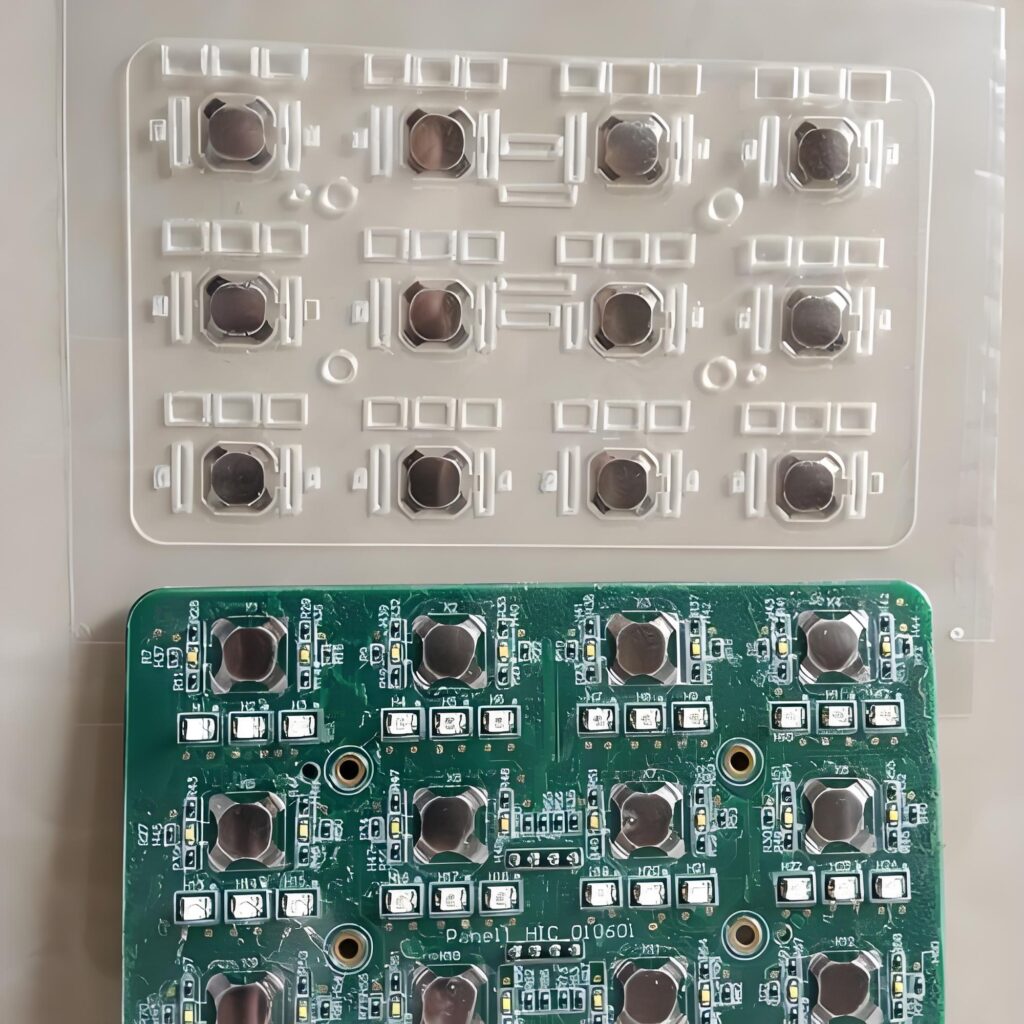

The tactile metal dome is located on top of the printed circuit board (PCB).

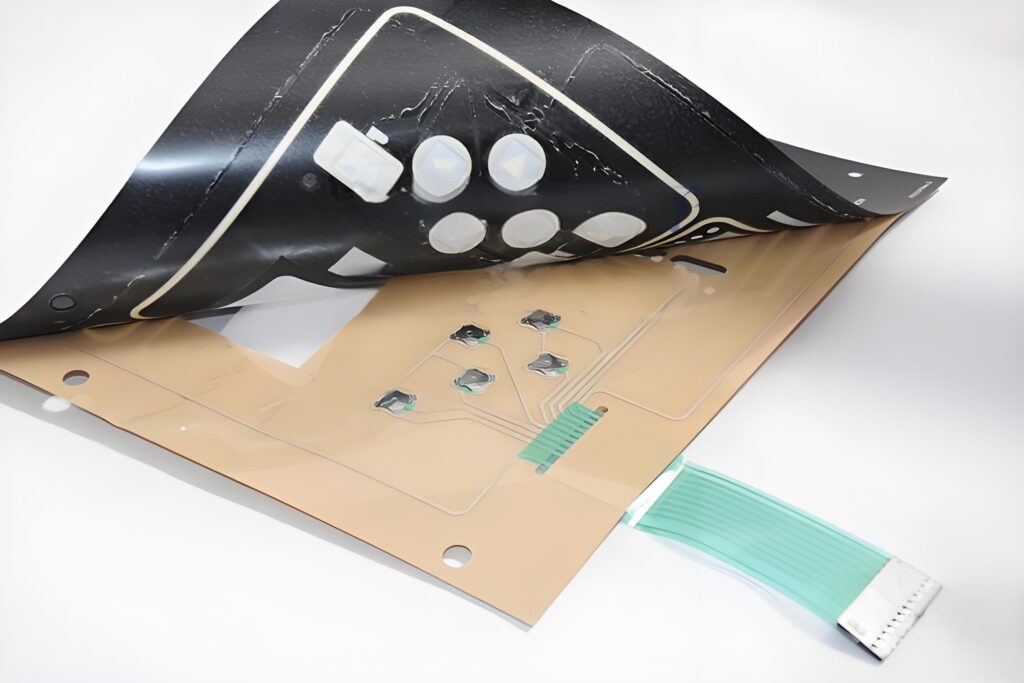

Firstly, make sure there is no dirty or any stains on the surface of printed circuit boards or metal dome array, make sure they are cleaning to assemble.

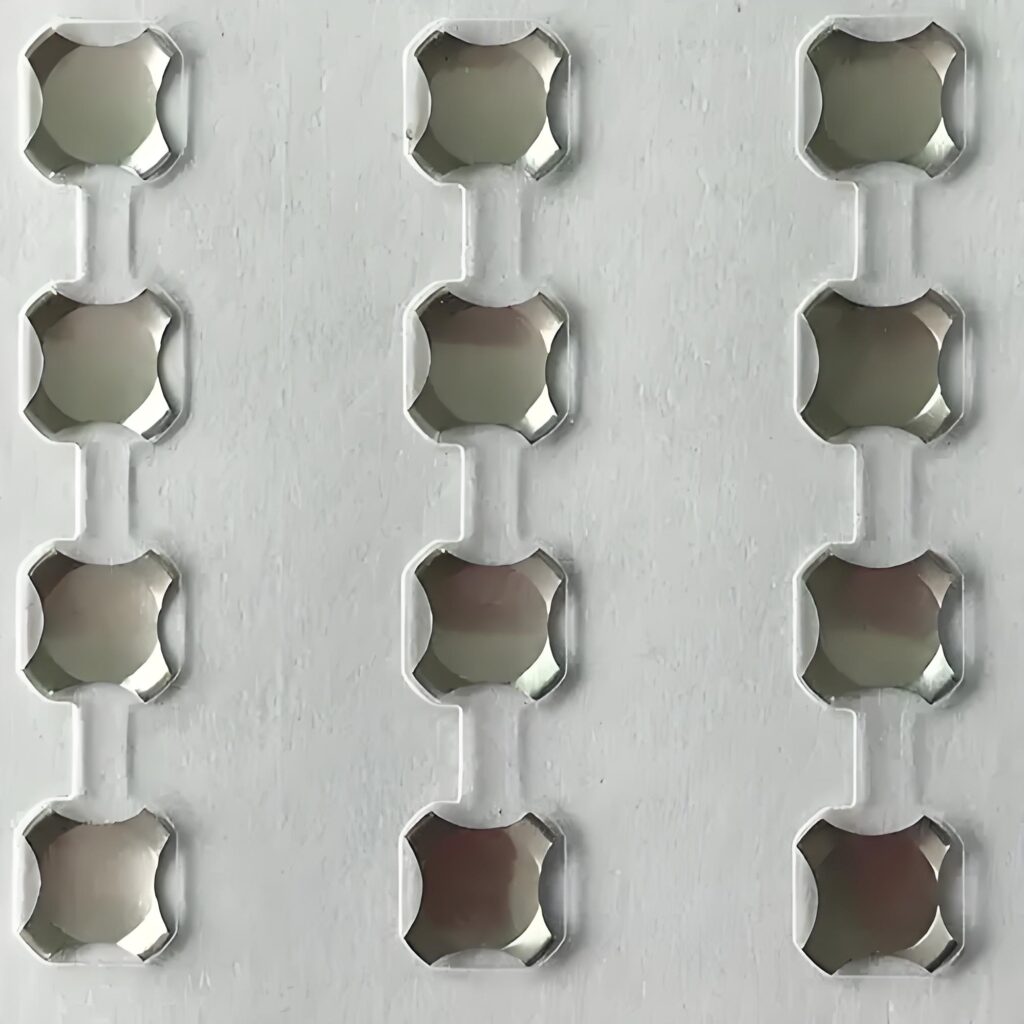

Align metal dome array with the PCB. Peel off the metal dome array from the release paper and then align it with the PCB through positioning holes, outline or mark legend printed on PCB.

Stick metal dome array with PCB firmly. Put the metal dome array with fixture or automatic machine carefully then press surface of dome array to make sure it adhere on PCB firmly.

Whether you’re using an application fixture or automatic equipment, when securing a dome with pressure-sensitive adhesive tape, it is crucial to move air out of the venting area so that the domes don’t “float.”

Floating happens when the air pocket around the dome causes the dome to stick to the top of the tape so that it is not resting securely on the circuit pad. To prevent this, place the domes with your pressure-sensitive adhesive tape directly onto the circuit board. Ensure the adhesive around the dome’s edges is secured to the circuit board and then moves outward to the adhesive edges. If the adhesive is too tight around the dome, it can cause the dome to collapse. This condition is also known as pre-load.

How do tactile dome designs affect PCB performance?

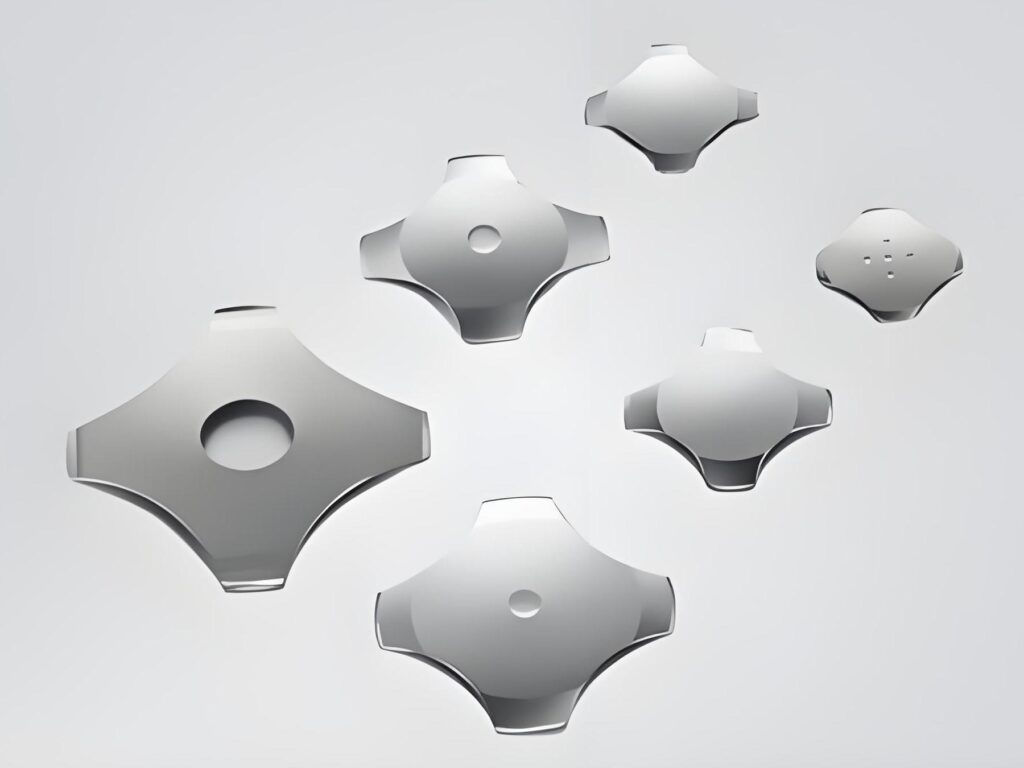

The shape, size, and force of a tactile dome influence the entire feel and functionality of the interface.

A taller dome may offer more tactile feedback. A flatter dome responds faster. Some domes are designed to require more actuation force, while others need only a gentle press.

All these variables impact how the dome interacts with the PCB. A poorly designed dome might cause inconsistent contact. That leads to delayed responses or missed signals. In contrast, a well-engineered dome switch PCB ensures consistent touchpoints and smooth operation every time.

BEST Technology, a leading name in dome technology, offers a wide range of domes customized for different applications. Whether it’s for a high-durability medical interface or a compact consumer device, each dome design affects how the switch feels—and how it performs.

How does a dome switch touch the PCB?

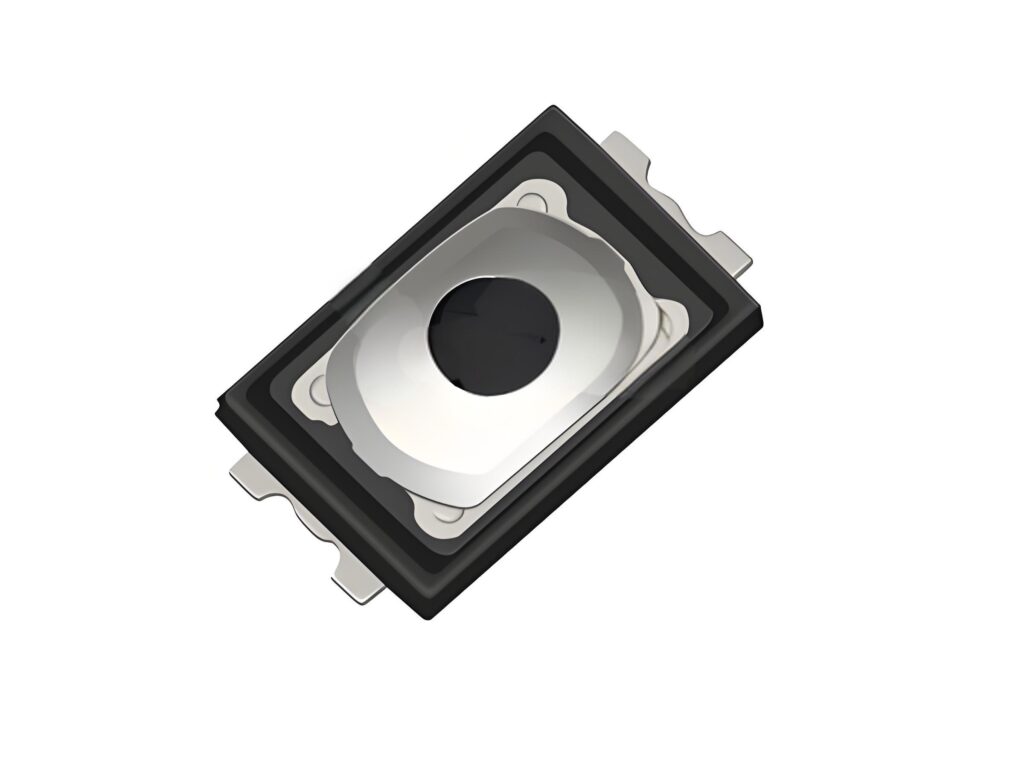

Most tactile domes have a slight curvature, almost like a shallow dish. At the center is a dimple or contact point. Around the outer edge, the dome sits suspended just above the PCB surface.

When force is applied, the dome deforms downward. Its center snaps into the contact pads on the PCB. This snap action creates a swift, clean connection with minimal resistance.

What makes this mechanism so brilliant is its speed. There’s no slow sliding or dragging. It’s a crisp, instant touch that minimizes signal delay and mechanical wear. That’s why snap dome switches are so often preferred in high-reliability electronics.

How is tactile feedback created in dome switch PCBs?

Tactile feedback is the sensation you feel when the dome collapses.

It’s created by the rapid release of stored energy inside the dome. As you press, the dome resists. Then suddenly, it gives way. That moment of collapse creates the signature “snap.”

This feedback helps users know their input was registered. No guessing. No repeated presses.

Tactile feedback also prevents accidental activation. You need just the right amount of pressure to trigger the switch. This feature is especially valuable in critical environments like medical equipment or industrial controls, where every action counts.

Why do dome switch keyboards feel responsive?

Dome switch keyboards use arrays of tactile metal domes under each key. A responsive, crisp typing experience that combines the softness of a membrane with the snap of a mechanical action.

What sets them apart is the precision of the feedback. Users feel a distinct click, often with minimal travel. This responsiveness gives users confidence that their input has been received.

Many dome switch keyboards are also quieter than mechanical ones. That makes them ideal for environments where noise matters—offices, hospitals, or shared workspaces.

Better still, dome switch keyboards are compact and lightweight. They take up less space without compromising performance. That’s why they’re popular in handheld devices, remote controls, and embedded systems.

What causes poor contact in a snap dome PCB switch?

While tactile domes are engineered for reliability, issues can still occur. The most common problem is poor contact. This happens when the dome doesn’t touch the PCB pads cleanly. The causes vary:

- Dust or debris between the dome and PCB

- Misalignment during assembly

- Worn or damaged domes

- Low-quality adhesive layers

- Excessive oxidation on the contact surfaces

When contact is compromised, the signal may become intermittent—or fail completely. In some cases, users may press harder to force a connection, which degrades the dome over time.

Fortunately, these issues are preventable. High-quality manufacturing, proper housing design, and careful dome selection greatly reduce the risk. Working with experienced suppliers like BEST Technology ensures higher production standards and long-term reliability.

What are the applications of dome switch pcb?

Tactile dome switch PCBs are everywhere. Their compact size, reliability, and cost-effectiveness make them ideal for countless industries.

In consumer electronics, dome switches power remote controls, handheld game consoles, and smart home devices. They offer just the right blend of sensitivity and durability.

In medical devices, dome switches are used in defibrillators, diagnostic tools, and control panels. The tactile feedback is essential, allowing medical staff to operate confidently—even in stressful situations.

Industrial control systems benefit from dome switches in ruggedized interfaces, where moisture, dust, and vibration can compromise other technologies. Their sealed design and tactile confirmation are ideal here.

Military and aerospace systems rely on dome switch PCBs for mission-critical interfaces. The stakes are high, and these switches deliver under pressure. Even in extreme conditions, they maintain precise contact and provide instant feedback.

Automotive applications also use dome switches in dashboard panels, keyless entry systems, and steering wheel controls. They’re durable, responsive, and easy to integrate into sleek designs.

From wearable tech to home appliances, the list of applications keeps growing. Whenever you need reliability, speed, and a tactile response—you can count on dome switch technology.

Conclusion:

Tactile metal domes make everyday interactions smoother, faster, and more reliable. Whether you’re designing a dome switch PCB for a medical device, a dome switch keyboard for a compact control panel, or integrating snap dome switches into high-end consumer electronics—every detail counts.

The right dome, properly aligned and thoughtfully chosen, elevates performance. It boosts user satisfaction. And it ensures your device performs exactly as intended, again and again.

If you’re looking for dependable tactile dome solutions, we’re here to help. At BEST Technology, we specialize in tactile dome manufacturing and custom switch assemblies that bring your product vision to life. Contact us today at sales@metal-domes.com